Verbatim, part of the Mitsubishi Chemical Holdings Group, has launched the butenediol-vinyl alcohol copolymer (BVOH), a water-soluble ...

Tag Archives: Filament

Bulked Steady Filament Nylon – The Bisouv Community

31

Mar

"

Get sample report

Bulked Continuous Filament Nylon Market Research Report is the n...

Fillamentum unveils first totally biodegradable filament NonOilen for 3D printing

31

Mar

The Czech 3D printing filament manufacturer Fillamentum has launched NonOilen, its first 100 percent biodegradable filament for 3D pri...

3D Printing Filament Materials Market Measurement,Share,Development Issue 2021 International Trade Demand, Key Findings, Regional Evaluation, Key Gamers Profiles, Future Prospects and Forecasts to 2027

31

Mar

Global Markt für 3D-Druckfilamentmaterialien Der Forschungsbericht enthält eine wichtige Marktanalyse, Markttreiber, Branchenbes...

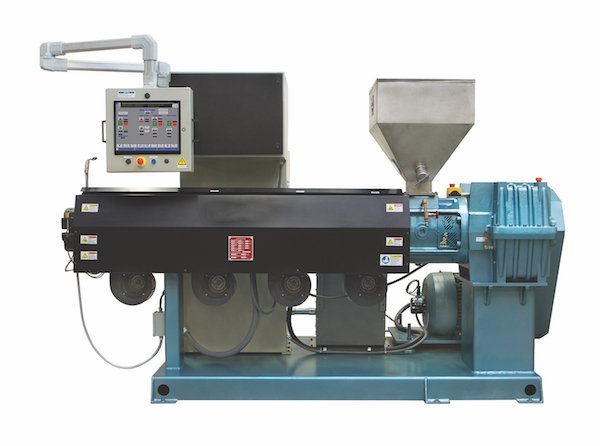

Leistritz Provides 3D Filament Line to Lab

30

Mar

Leistritz recently installed a ZSE-3D twin screw extrusion line in its process laboratory in Somerville, NJ. The ...

Davis-Customary to showcase TPE tubing and ABS filament line at MD&M West 2020

29

Mar

Davis-Standard will exhibit an ongoing TPE tubing and ABS filament line during MD&M West (February 11-13).The line ...

Taulman3D Releases Nylon 680 3D Printer Filament – FDA Permitted for Meals Contact & Extra – 3DPrint.com

27

Mar

When it comes to the materials science behind 3D printer fila...

Complete Report on 3D Printer Filament Supplies Market 2021

26

Mar

Download sample report

3D Printer Filament Materials Market Research Report is the new statistical data source added by A2Z...

Bulked Steady Filament Nylon Market in Canada – The Bisouv Community

25

Mar

"

Get sample report

Bulked Continuous Filament Nylon Market Research Report is the n...