Anticipating the expansion of bonded metal printing by severa...

Tag Archives: Printing

New Aquasys 120 3D Printing Help Supplies Obtainable in 1.75 mm and a pair of.85 mm Diameter Filament

26

Dec

Summary of the press release:Dissolves up to six times faster than PVA and remains stable when higher temperatures or more demandi...

Cyrus 3D printers Releases New 3D Printing Filament Vary

25

Dec

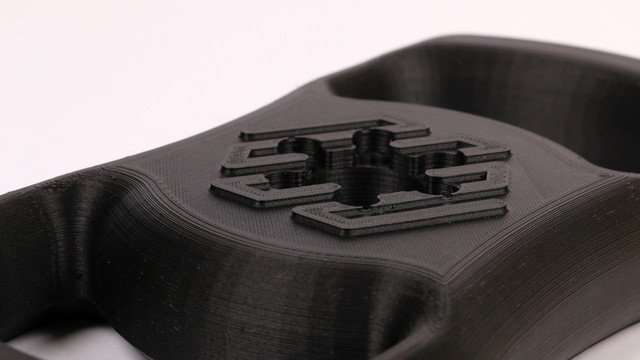

3D printed terminator skeleton

A good print really depe...

3D Printing Filament Black Friday Offers

24

Dec

Published on November 24, 20173D Insider is ad-supported and earns money with clicks and other opportunities.Everyone knows that h...

Markforged Releases Carbon Fiber 3D Printing Filament > ENGINEERING.com

24

Dec

Markforged launches carbon fiber 3D printing filamentMichael Molitch-Hou published June 29, 2016 |

To add extra strength to c...

This is one of the best 3D printing filament cash should buy

23

Dec

Filament is to 3D printers what gasoline is to cars. You need it to run your machine. You can get it from different places; an...

Keene Village Plastics acquires 3D printing filament producer MakeShaper, expands attain to hobbyist market

22

Dec

Keene Village Plastics (KVP), an Ohio-based manufacturer of 3D printing filaments, has announced the acquisition of another US mate...