“

The Nylon 6 Filament Yarn Market research report is the new statistical data source adde...

Tag Archives: Nylon

Breathe-3DP unveils new nylon filament

28

Dec

Breathe-3DP has introduced its Phoenix filament for those looking for a custom made nylon filament that simply raises the bar.

It was ...

FIASWI towards anti-dumping responsibility on nylon filament yarn

23

Dec

The Indian Artificial Silk Weaving Association (FIASWI) and Surat-based Loom Weaving Associations, led by FIASWI chairman Bharat Gandhi...

World Bulked Steady Filament Nylon Market 2020 with COVID-19 After Results – Development Drivers, High Key Gamers, Trade Segments and Forecast to 2025

23

Dec

Global Bulked Continuous Filament Nylon Market 2020, by Manufacturers, Type and Application, Forecast to 2025 specializes in ...

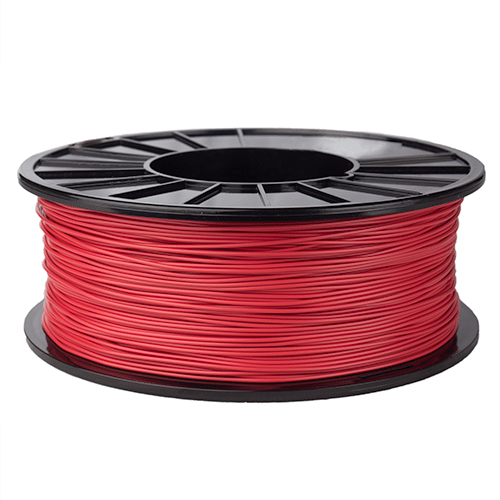

Sturdy Nylon Filament: Properties, Easy methods to Use, and Finest Manufacturers

23

Dec

3D Insider is ad-supported and earns money with clicks and other opportunities.Nylon is a fairly common material, and you've probably h...

The International Nylon Filament Yarn Market is forescasted to develop to greater than 7,000 thousand metric tons through the interval 2018-2022

23

Dec

LONDON, October 24, 2018 / PRNewswire / - About nylon filament yarnNylon filament yarn is a long continuous fiber that is widely used ...

FIASWI protests anti-dumping obligation on nylon filament yarn | Surat Information

23

Dec

SURAT: The Indian Artificial Silk Weaving Association (FIASWI) and Powerloom Weaving Associations on Saturday urged the chairman of the...

DGTR imposes anti-dumping obligation on imported nylon filament yarn | Surat Information

22

Dec

SURAT: To the disappointment of the Powerloom weavers, the General Directorate for Trade Aids (DGTR) recommended an anti-dumping duty o...

![3D Printing Materials Market by Type Plastics (PLA, ABS, PVA), Metals (Titanium, Steel, Silver), Ceramics]; By Form (Filament, Powder, Liquid); Application (Aerospace, Automotive, Industrial, Healthcare) - (2013](https://3dfilamentzoom.com/wp-content/uploads/2020/12/prn_facebook_sharing_logo.jpg)