You may want to sit down because this one is exciting. The virtual foundry has just launched Filamet ™, a new metal infused filament that turns any FDM 3D printer into a metal 3D printer!

Really…

We have just gotten used to the fact that only high-end printers can handle metal and most mortals have to get by with simple plastics. That just changed. You can now print copper and bronze on any 3D printer.

This new filament from the Wisconsin-based company could literally be a game changer and disrupt the current course of 3D Printed Metal. They came out with copper and bronze, but you can expect more metals to be seen in the near future.

More than just metal.

The patented process of the virtual foundry not only works with metal, but will also be equipped with 3D-printable glass and ceramic products over the next 6 months. Maybe you don’t need to upgrade your 3D printer after all, and thanks to this quantum leap in materials science, even the simplest desktop unit could turn into a complete manufacturing facility.

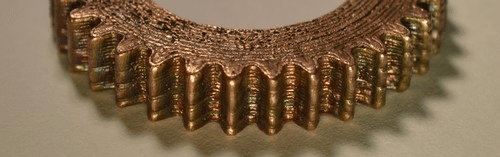

How does it work? It’s basically a heavily infused plastic, just enough plastic to get through your current printer. Currently this is only 11.5%, an amount that was below the theoretical limit a year ago. The remaining 88.5 mass% are high-purity metal powder. The prints can then simply be buffed or, interestingly, post-processed to remove the small amount of plastic. The resulting product is 99 +% pure metal that is as pure as many of us will ever need. The virtual foundry says they keep improving the process and expect future versions to be closer to just 8% plastic.

Another great Kickstarter success story?

This project showed up on Kickstarter last year and raised 135% of target funding. However, the virtual foundry had a mission to bring metal production to our desktops before 3D printing was even an option. It used to work with cold casting and electroforming, but now technology has caught up and 3D printing seems to have given them the answer.

We don’t have the finished product in our hands yet. However, the big start at the Hubble Auditorium in Lockheed-Martin suggests the team really cracked the code.

“Printer manufacturers have struggled for years to get metal printing within the price range of the average sole proprietorship or small business,” said Bradley Woods, the man behind this technical breakthrough. “Filamet ™ has the opposite strategy. Instead of impairing the high-end, only the functions of current 3D printers are expanded. “

“We expect materials to be a big part of near-term product innovation in the 3D printing market. Our company offers an instant solution for creating real and useful metal prints on the desktop 3D printer you already own. “

Professionalize your home printer

This filament could make your desktop printer a rival to the reputable commercial machines, and even turn out to be better. That’s because metal printers are notoriously slow, and a large printer can actually take 48 hours to make a single print.

While the end result may be spectacular, even if you could afford to have one in your home workshop, it might not fit your workflow.

Consumer printers are designed for the average user and therefore offer a realistic tradeoff between price, resolution and speed. With this metal filament, your home 3D printer could become a real manufacturing weapon. We can suddenly make statues and parts out of copper and bronze without having access to a furnace, and that could be a revolution in itself.

Prints can take less than five hours with a consumer printer, and this new material is big news even for large businesses.

Companies are in this too

The technology has attracted big names like Calvin Klein and a company looking to license the consumable parts manufacturing technology for its facility that 3D prints uranium fuel cells for nuclear reactors. The technology works with any 3D printer, meaning that even commercial companies with multiple printer scans are now using their simpler units for faster, cheaper production.

This opens up so many new opportunities and science itself could be a launch pad for other companies to develop their own innovations. We have often said that the biggest step forward will come from materials, but even we haven’t seen any company turn today’s printers into complete production lines for metals, glass and ceramics.

We can’t wait to see the products in action and test this filament for ourselves. If it turns out to be half what the claims are, it can change everything.

http://www.theVirtualFoundry.com & [email protected]

More pictures under http://www.thevirtualfoundry.com/showcase/