Manufacturer of FFF 3D printers INTAMSYS is the world’s first global reseller of polymer specialists VictrexThe new polyaryletherketone (PAEK) filament – VICTREX AM 200. Through the collaboration, INTAMSYS is also the first company in the filament fusion network proposed by Victrex to facilitate and promote the use of AM 200 and future PAEK-based filaments around the world.

Jakob Sigurdsson, CEO of Victrex, explains: “This new generation of PAEK materials for additive manufacturing from Victrex represents an important step forward and we are now excited to be working closely with INTAMSYS. Due to the excellent cooperation with companies and institutions that pursue innovations in additive manufacturing, such as INTAMSYS, as well as the continued research of Victrex, we have made sustainable progress in the development of truly innovative components that rely on the design freedom of additive manufacturing in combination with the high PAEK performance. “

Part printed in VICTREX AM 200. Photo via INTAMSYS.

Optimized for additive manufacturing

According to INTAMSYS, most of the PEEK and PEKK filaments available on the market today, although suitable for 3D printing, have been formulated for traditional manufacturing processes such as injection molding. As a result, they may not be optimal for the additive extrusion process with poor interlayer adhesion and poor Z strengths.

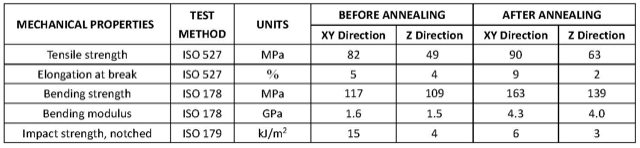

Victrex’s PAEK material is believed to provide relief as the company claims the AM 200 was specifically designed and optimized for 3D printing. When using an FFF 3D printer, the filament should have both higher Z and XY strengths compared to existing PAEK material.

Put the AM 200 to the test

INTAMSYS carried out some internal tests with AM 200 FUNMAT PRO 410 3D printers to see what Victrex was raving about. With XY strengths of up to 90 MPa and elongations of up to 9%, the filament turned out to be a worthy competitor to PEEK. The results also show that AM 200 has better interlayer adhesion than other non-optimized PAEK materials – at least on an INTAMSYS machine.

The duo attributes this to its slow rate of crystallization and refined viscosity, which allow for easier flow through the nozzle. The low shear rates of the material also result in greater outdoor stability once extrusion has taken place. The high wear and temperature resistance of the AM 200 as well as its fatigue and corrosion resistance make it suitable for long-term chemical contact applications.

Polyketone family polymers are usually quite similar in properties, but can have different uses. Chemical company Evonik recently his Vestakeep i4 3DF PEEK filament specially developed for medical implants. The material meets the requirements of ASTM F2026 and is suitable for long-term contact with body fluids.

Elsewhere, EOS has before released a powdery high performance, carbon fiber reinforced PEKK material for its polymer SLS systems. The high temperature HT-23 material was developed in collaboration with Boeing and is primarily for aerospace applications.

Subscribe to the 3D printing industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us Twitter and continue to like us Facebook.

Looking for a career in additive manufacturing? visit 3D print jobs for a selection of roles in the industry.

The picture shown shows a part printed in VICTREX AM 200. Photo via INTAMSYS.