A filament match for house—silk is confirmed to thrive in outer house temperatures

Photo credit: CC0 Public Domain

Their initial discovery appeared to be a contradiction in terms, as most other polymer fibers became brittle in the cold. However, after many years of working on the problem, the research group found that the cryogenic toughness of silk is due to its nanoscale fibrils. The submicroscopic order and hierarchy enables a silk to withstand temperatures down to -200 ° C. And possibly even lower, which would make these classic natural luxury fibers ideal for applications in the depths of cool space.

The interdisciplinary team examined the behavior and function of several animal silks that had cooled to a temperature of -196 ° C. The fibers included spider silk, but the study focused on the thicker and much more commercial fibers of the wild silkworm, Antheraea pernyi.

In an article published today in Materials Chemistry Frontiers, the team was not only able to show that silk increases its toughness in conditions where most materials would become very brittle. In fact, silk seems to contradict the basic understanding of polymer science in that it does not lose in really cold conditions, but rather improves in quality by becoming both stronger and more ductile. This study examines the how and explains the why. It turns out that the underlying processes are based on the many nanoscale fibrils that make up the core of a silk fiber.

Consistent with traditional polymer theory, the study assumes that the individual fibrils actually get stiffer as they get colder. The novelty and importance of the study lies in the conclusion that this stiffening leads to increased friction between the fribrillae. This friction in turn increases the rupture energy deflection and at the same time resists the slipping of the fibrils. A change in temperature would also modulate the force of attraction between individual silk protein molecules, which in turn affects the core properties of each fibril, which is made up of many thousands of molecules.

It is important that research is able to describe the hardening process on both a micrometer and nano scale. The team concludes that any crack that tears through the material will be redirected every time it hits a nanofibril, forcing it to lose more and more energy in the many detours it has to negotiate . And so a silk fiber only breaks when the hundreds or thousands of nanofibrils have first stretched and then slipped and then all torn individually.

The discovery pushes boundaries by examining a material in the conceptually difficult and technologically challenging realm that not only spans the micrometer and nanoscale, but also needs to be examined at temperatures well below any freezer. The size of the scales examined ranges from the micrometer size of the fiber to the submicrometer size of a filament bundle up to the nanoscale of the fibrils and not least to supra-molecular structures and single molecules. Against the backdrop of cutting edge scientific and futuristic applications, it should be remembered that silk is not only 100% organic fiber, but also an agricultural product with thousands of years of research and development.

It appears that this study has far-reaching implications by suggesting a wide variety of novel uses for silk, ranging from novel materials for use in the polar regions of the world to novel composites for light aircraft and kites used in the Strato and Mesogalls may even fly giant webs spun by robotic spiders to catch astro trash in space.

Professor Fritz Vollrath of the University of Oxford Zoological Institute said, “We anticipate that this study will lead to the development and manufacture of new families of tough structural filaments and composites, using both natural and silk-inspired filaments for use in extremely cold conditions can be used as a room. ‘

Prof. Zhengzhong Shao of the Macromolecular Science Department at Fudan University in Shanghai said, “We conclude that the exceptional mechanical toughness of silk fibers at cryogenic temperatures is due to their highly oriented and oriented, relatively independent and stretchable nanofibrillary morphology.”

Dr. Juan Guan of Beihang University in Beijing said, ‘This study provides new insights into our understanding of the structure-property relationships of high-performance natural materials that we hope will lead to the manufacture of man-made polymers and composites for low temperature and high impact applications. ‘

And Dr. Chris Holland of Sheffield University, leader of a pan-European research consortium on novel, sustainable biofibers based on knowledge about the spinning of natural silk, said: “Natural silks continue to be the gold standard materials for fiber production. The work here shows that not only the chemistry, but also the way in which silks are spun and consequently structured, is the secret of their success. ‘

The next steps of research will continue to test the amazing properties. A spin-out company, Spintex Ltd from Oxford University, funded in part by an EU H2020 grant, is researching spider silk proteins in the spider’s nature, focusing on copying the submicron structures of bundled fibrils.

Silk

- Natural silks are environmentally friendly because the animal flings them from aqueous protein melts at ambient temperatures and low pressure.

- Many silks are biocompatible, making them excellent materials for use in medical devices. Silks are light and tend to be very tough, suggesting their use in light applications where a lot of energy must be absorbed by the material.

- All silks are biologically disposable and consist entirely of natural amino acid building blocks that can easily be integrated into the natural cycle of decay and rebuilding.

- Last but not least, there is a wealth of information in silk about protein folding and the way nature makes extraordinary polymer structures.

Nanomaterials help spiders spin the toughest material available from Oxford University

Quote: A filament suitable for space – silk has been proven to thrive at space temperatures (2019, October 3), which were published on December 21, 2020 at https://phys.org/news/2019-10-filament-spacesilk-proven-outer- space .html

This document is subject to copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.

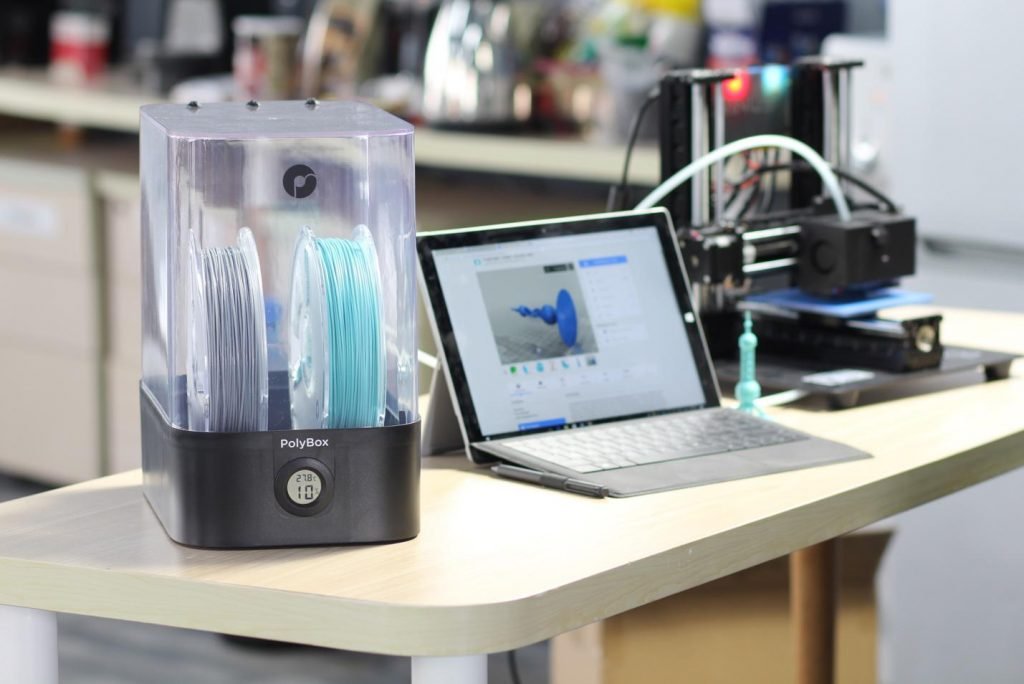

The Polybox ™ is a dry storage box that allows you to print and store your threads in their optimal environment ensuring the best print quality from the beginning of the spool to the end. The PolyBox ™ comes with a 150 cm long filament guide tube to ensure that the filament is protected from the spool to the hot end. There are six filament exit holes in a reversible housing. Whether your printer is front, rear, or side-fed, there is an orientation that will suit your setup.

The Polybox ™ is a dry storage box that allows you to print and store your threads in their optimal environment ensuring the best print quality from the beginning of the spool to the end. The PolyBox ™ comes with a 150 cm long filament guide tube to ensure that the filament is protected from the spool to the hot end. There are six filament exit holes in a reversible housing. Whether your printer is front, rear, or side-fed, there is an orientation that will suit your setup. The Polybox ™ regulates moisture with large desiccant bags in the base of the device. This cheap, simple solution provides a dry environment for filament storage and printing. The desiccants can be dried and reused once they have reached their maximum water absorption. With four bearing-wrapped steel bars, two spools can rotate independently for double extrusion, or the PolyBox ™ can hold a 3kg spool for long prints or industrial use. The humidity in the box can be monitored with a high-precision thermo-hygrometer on the front of the device.

The Polybox ™ regulates moisture with large desiccant bags in the base of the device. This cheap, simple solution provides a dry environment for filament storage and printing. The desiccants can be dried and reused once they have reached their maximum water absorption. With four bearing-wrapped steel bars, two spools can rotate independently for double extrusion, or the PolyBox ™ can hold a 3kg spool for long prints or industrial use. The humidity in the box can be monitored with a high-precision thermo-hygrometer on the front of the device. The PolyBox ™ is a simple solution to the growing problem of the proper storage of 3D printing filaments. With Polymaker Industrial offering 4 grades of nylon next year and Polymaker launching its own nylon next year, the need to properly store your filaments is more important today than ever. Why should we be held back by moisture absorption when innovative materials open new doors in the 3D printing industry?

The PolyBox ™ is a simple solution to the growing problem of the proper storage of 3D printing filaments. With Polymaker Industrial offering 4 grades of nylon next year and Polymaker launching its own nylon next year, the need to properly store your filaments is more important today than ever. Why should we be held back by moisture absorption when innovative materials open new doors in the 3D printing industry?