Filament Dyeing | Hackaday

Manufacturers dye all kinds of 3D printer filament on their factory lines. why can’t we [Richard] goes one step further and creates its own multi-colored nylon rollers. Printing with these rolls creates a living pattern that simply demands our attention and asks us: how on earth?

[Richard’s] Tie-dye adventure is neatly documented in the blog. He simply spools up a roll of nylon and dyes subsections of the spool a different color. When the filament is “palletized” to taste, parts of the printer will burst with a noticeable rib pattern.

It is worth noting that nylon is extremely hygroscopic, and dyeing filaments in a bath full of colored liquid is sure to add moisture. On the other hand, the ability of nylon to absorb water could be why it stains so well. Even so, the filament must be oven dried (or equivalent) to print successfully. After drying, [Richard] doesn’t seem to have any printing issues and the results speak for themselves

3D printers may be frequent fliers on these sites, but we still love to see small changes that improve visual appeal. In addition, this trick produces spectacular results without any changes to the printer. If this job is just too much work for you, we recommend using a felt-tip pen.

Continue reading “Tie-Dyed Filament Sings With Color”

![3D Printing Materials Market by Type Plastics (PLA, ABS, PVA), Metals (Titanium, Steel, Silver), Ceramics]; By Form (Filament, Powder, Liquid); Application (Aerospace, Automotive, Industrial, Healthcare) - (2013](https://3dfilamentzoom.com/wp-content/uploads/2020/12/prn_facebook_sharing_logo.jpg)

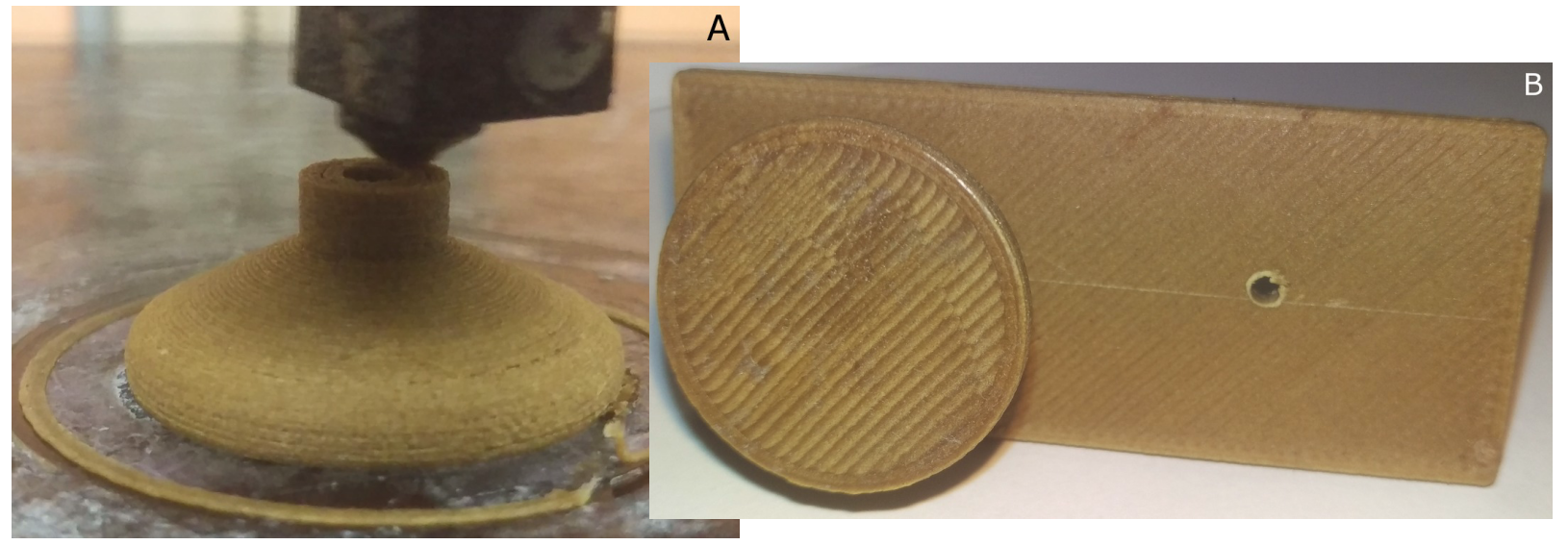

A door knob printed with the wooden thread. Image via Forest Products Society

A door knob printed with the wooden thread. Image via Forest Products Society

KVP’s range of glow-in-the-dark PETG filaments. Photo via CIP.

KVP’s range of glow-in-the-dark PETG filaments. Photo via CIP.

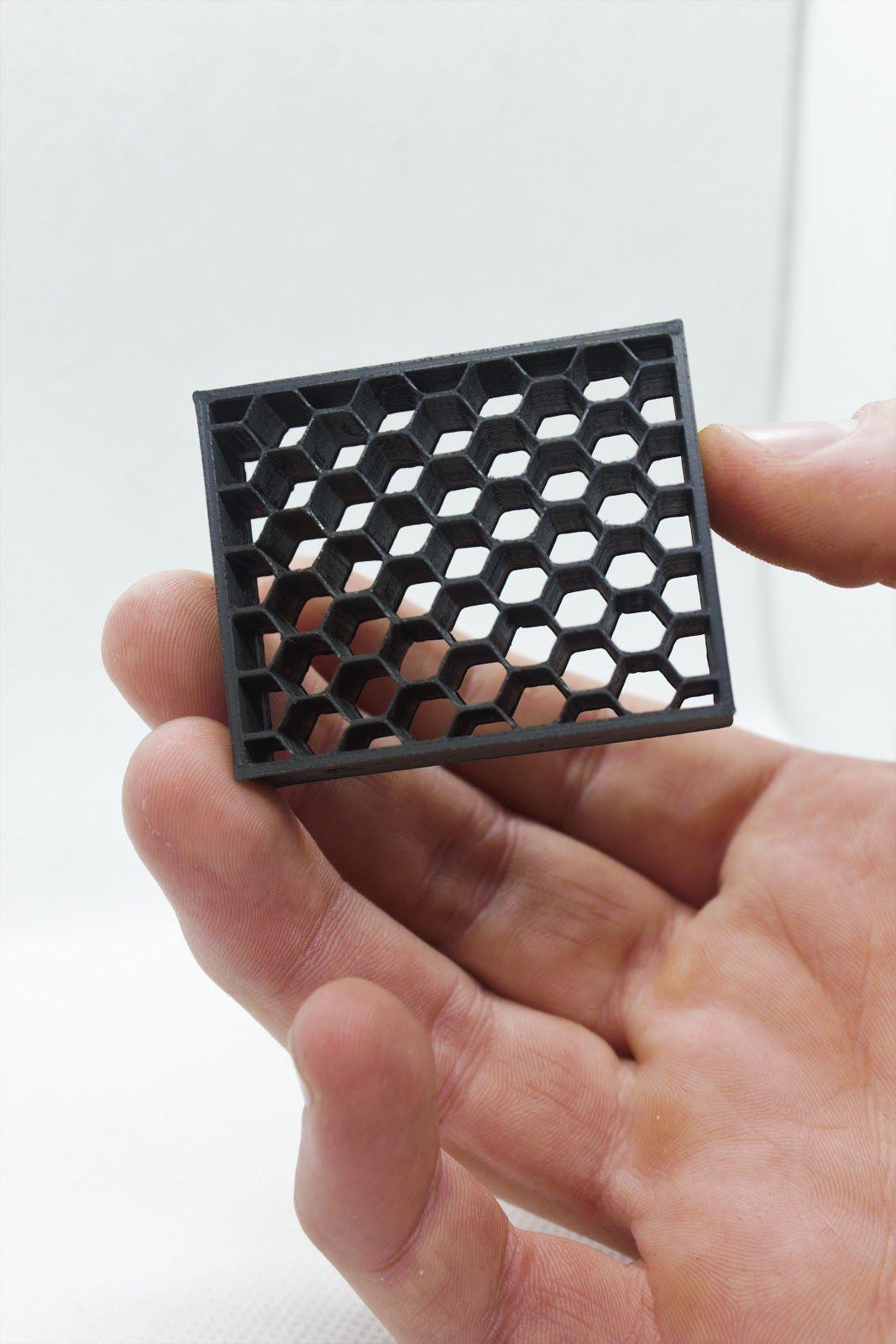

Part 3D printed with Addbor N25 filament. Photo via Additive Composite.

Part 3D printed with Addbor N25 filament. Photo via Additive Composite.

Ben Patterson / IDG

Ben Patterson / IDG Ben Patterson / IDG

Ben Patterson / IDG