MakerBot rolls out new glow-in-the-dark filament and extra

Some of the most interesting and affordable 3D printers come from MakerBot. The company also has a cool 3D desktop scanner that can take just about anything that fits on it and make a digital copy of it that you can use to print your own 3D version. MakerBot has announced that it is shipping some new filaments that will bring new colors and artistic possibilities to the owners of the 3D printers.

MakerBot has announced three new filaments that will be available online and in the Makerbot Store in New York. One of the filaments consists of a special phosphor dye and is called MakerBot Glow-In-The-Dark PLA filament. How intensely the new filament glows depends on the intensity of the light with which it is charged.

MakerBot says the brighter the light, the brighter the glow the filament creates. Any light source can be used to load the filament. Charging takes 2 to 3 minutes, depending on the intensity of the light source. Items printed with the new glow-in-the-dark filament can be recharged repeatedly by placing them in front of a light source for a few minutes.

MakerBot is also launching new Warm Gray and Cool Gray PLA filaments. These colors are aimed at professionals using the Replicator 2 Desktop 3D printer. The glow-in-the-dark filament costs $ 130 for a 1kg spool. Both gray colors are available in 1kg spools for $ 48 each.

SOURCE: MakerBot

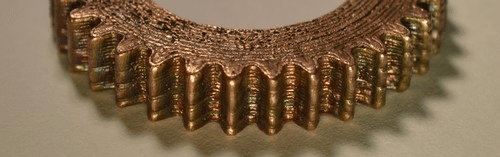

In addition to working with graphene, the company has developed a number of filaments made from various specialty materials, including wood, glow in the dark, and of course conductive. The latest product is a magnetic filament, which is available now in the Graphene 3D Lab’s Filament Store, BlackMagic3D, and on Amazon. The iron-based filament made from a ferro-magnetic PLA material is described as ideal for 3D printing industrial components such as sensors, motors and mechanical actuators.

In addition to working with graphene, the company has developed a number of filaments made from various specialty materials, including wood, glow in the dark, and of course conductive. The latest product is a magnetic filament, which is available now in the Graphene 3D Lab’s Filament Store, BlackMagic3D, and on Amazon. The iron-based filament made from a ferro-magnetic PLA material is described as ideal for 3D printing industrial components such as sensors, motors and mechanical actuators.

In addition to the numerous industrial applications for which the filament is expected to be suitable, it has great potential in education. Magnets are fun in and of themselves, but having kids 3D printing their own magnets is another great way to incorporate 3D printing into science classes. And Graphene 3D Labs isn’t done yet.

In addition to the numerous industrial applications for which the filament is expected to be suitable, it has great potential in education. Magnets are fun in and of themselves, but having kids 3D printing their own magnets is another great way to incorporate 3D printing into science classes. And Graphene 3D Labs isn’t done yet.