The vibrant filament extrusion 3D printing community in Argentina is growing rapidly, measured by the amount of filament consumed. Pr...

Tag Archives: Media

M. Holland now distributing BASF Ultrafuse 316L steel composite filament » 3D Printing Media Community

09

Jan

M. Holland Company, a distributor of thermoplastic resin materials, has announced an expanded sales partnership with BASF 3D Printing ...

Hemp PLA Filament, Entwined, Launched by 3D Gas » 3D Printing Media Community

19

Dec

The wait - 3D printing with hemp filament! Entwined is a 3D printing filament made from industrial hemp grown and processed in the...

RIZE launches RIZIUM Glass Fiber composite filament » 3D Printing Media Community

19

Dec

The 3D printing company RIZE has expanded its material portfolio with the introduction of RIZIUM Glass Fiber (GF), a composite filamen...

colorFabb unveils varioShore TPU filament with tunable flexibility » 3D Printing Media Community

15

Dec

The Dutch filament manufacturer colorFabb has added a new filament to its constantly growing portfolio. The 3D printing material c...

MakerBot releases PETG specialty filament for METHOD 3D printer » 3D Printing Media Community

14

Dec

3D printer manufacturer MakerBot expands its material portfolio for its METHOD 3D printer to include the approval of polyethylene tere...

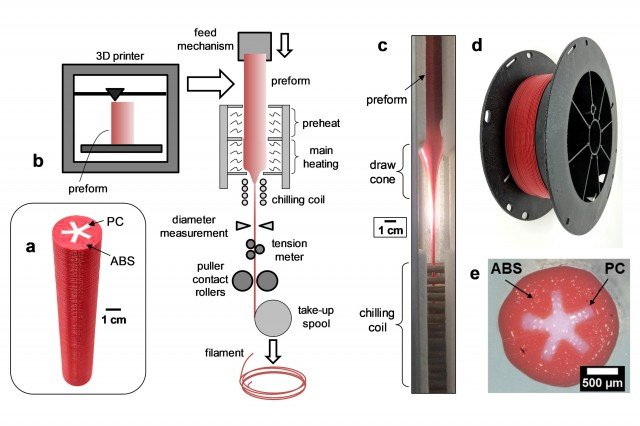

Multi-polymer filament from the US Military » 3D Printing Media Community

12

Dec

The U.S. Army just unveiled a new type of multipolymer filament for commonly used 3D printers for desktop material extrusion. The new...

Abrasive Nylon Brush Filaments-EMEA Market Dimension, Alternatives, Dynamic, Outlook and Forecast To 2027 – Cheshire Media

02

Dec

Fort Collins, Colorado - Global Abrasive Nylon Brush Filaments-EMEA Market report on in-depth research, sales estimate and growth forec...