March 9, 2016 | From Alec

Tag Archives: Materials

3D Printing Supplies Market by Kind Plastics (PLA, ABS, PVA), Metals (Titanium, Metal, Silver), Ceramics]; By Type (Filament, Powder, Liquid); Software (Aerospace, Automotive, Industrial, Healthcare) – (2013

22

Dec

LONDON, May 23, 2016 / PRNewswire / - With 3D printing or additive manufacturing (AM), a 3D model available to us is converted into a ...

The Division 2 supplies information: easy methods to farm Printer Filament, normal, and uncommon supplies

16

Dec

If finding a ton of loot in the rundown streets of a post-epidemic DC is not enough for you, you can make your o...

MakerBot establishes METHOD Supplies Program to increase 3D printing filament vary

14

Dec

MakerBot, the Brooklyn-based manufacturer of the METHOD The 3D printer has launched the METHOD Materials Development Program and Ma...

Developments in Water-Soluble Supplies for 3D Printing Assist Filament – 3DPrint.com

13

Dec

A new material has been developed that is ideally suited as a...

Newest report on 3D Printer Filament Supplies Market Development Evaluation, Alternatives, Developments, Developments and Forecast – Murphy’s Hockey Regulation

12

Dec

2020 Latest report on 3D printer filament materials market

Los Angeles, USA, December 2020: The report, titled Global 3D ...

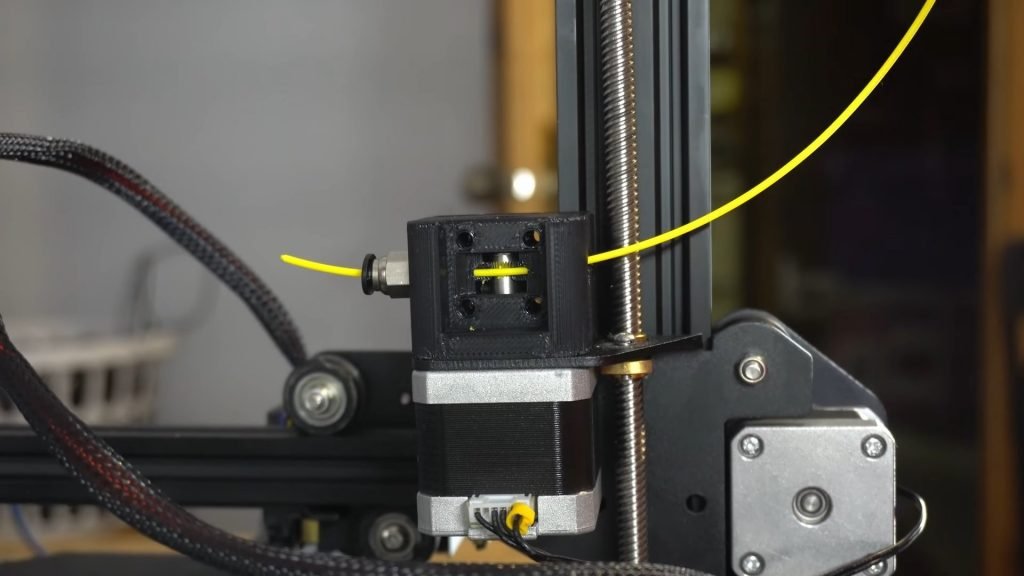

Ender 3 (Professional/V2) Filament Information: Supplies You Can 3D Print – All 3DP

11

Dec

Ender 3 (Pro / V2) Filament Guide: Materials You Can 3D Print in 3D

3D Printer Filament Supplies Market Evaluation, Income, Worth, Market Share, Development Fee, Forecast To 2026 – Murphy’s Hockey Legislation

04

Dec

IndustryGrowthInsights (IGI), one of the world's leading market research companies, has released a new report on the glob...

12

![3D Printing Materials Market by Type Plastics (PLA, ABS, PVA), Metals (Titanium, Steel, Silver), Ceramics]; By Form (Filament, Powder, Liquid); Application (Aerospace, Automotive, Industrial, Healthcare) - (2013](https://3dfilamentzoom.com/wp-content/uploads/2020/12/prn_facebook_sharing_logo.jpg)