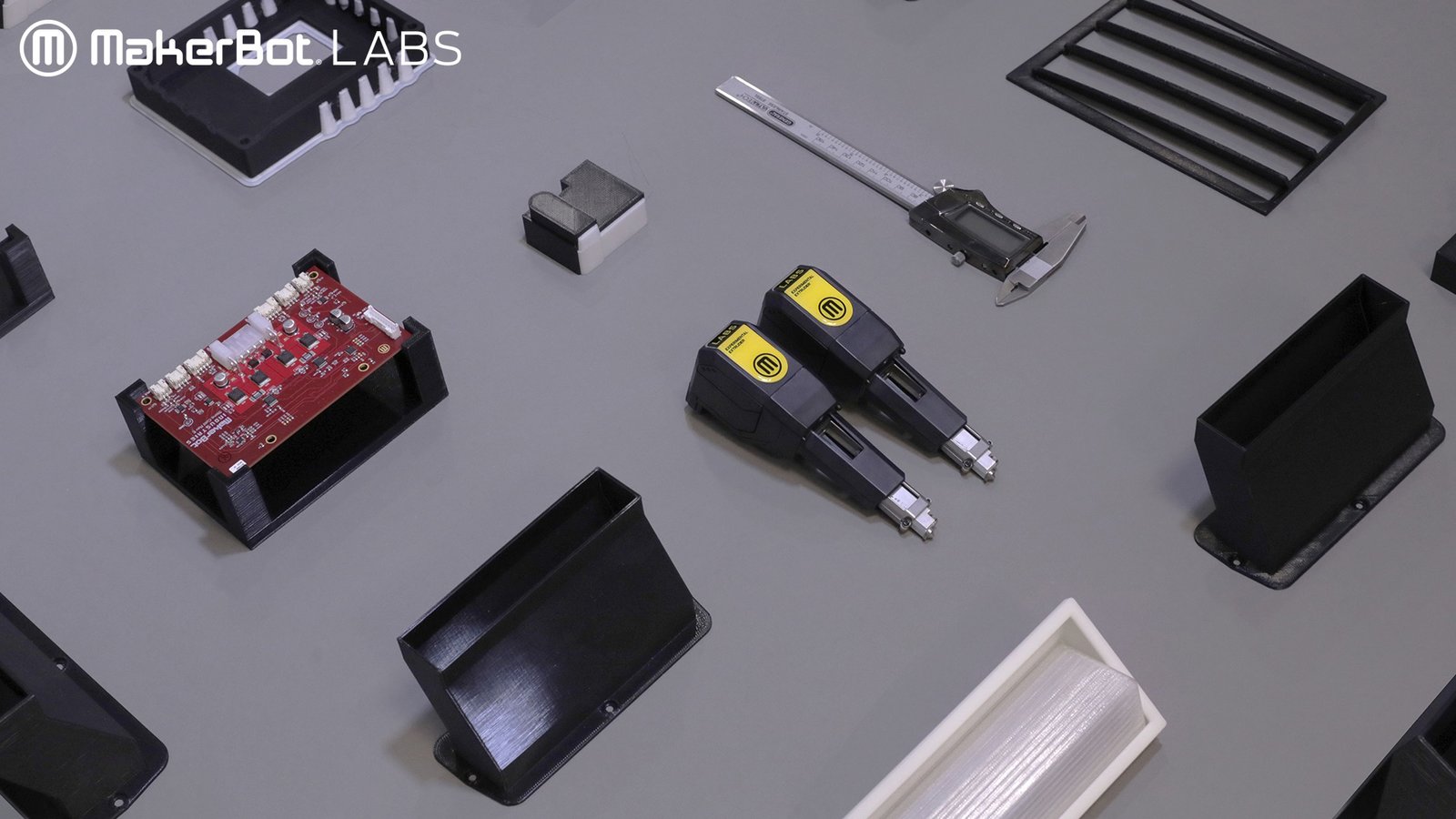

MakerBot, the Brooklyn-based manufacturer of the METHOD The 3D printer has launched the METHOD Materials Development Program and MakerBot LABS Experimental Extruder to expand the range of filaments used in its systems.

As the first partner Jabil, CHEMISTRY, Polymaker, and Mitsubishi Chemical are working to qualify filaments for use in the METHOD platforms. Additionally, the MakerBot LABS Experimental Extruder aims to improve the settings for customization and enable printing of high temperature materials.

“The MakerBot METHOD platform provides engineers with features previously only available on much more expensive industrial 3D printers,” said Nadav Goshen, CEO of MakerBot.

“With these features, METHOD 3D printers can achieve industrial reliability, precision, and engineering performance by closely controlling the entire printing environment from the heated chamber to the sealed filament shafts and power extruders. We also know that many of our customers want the opportunity to experiment with different materials to explore new 3D printing applications. “

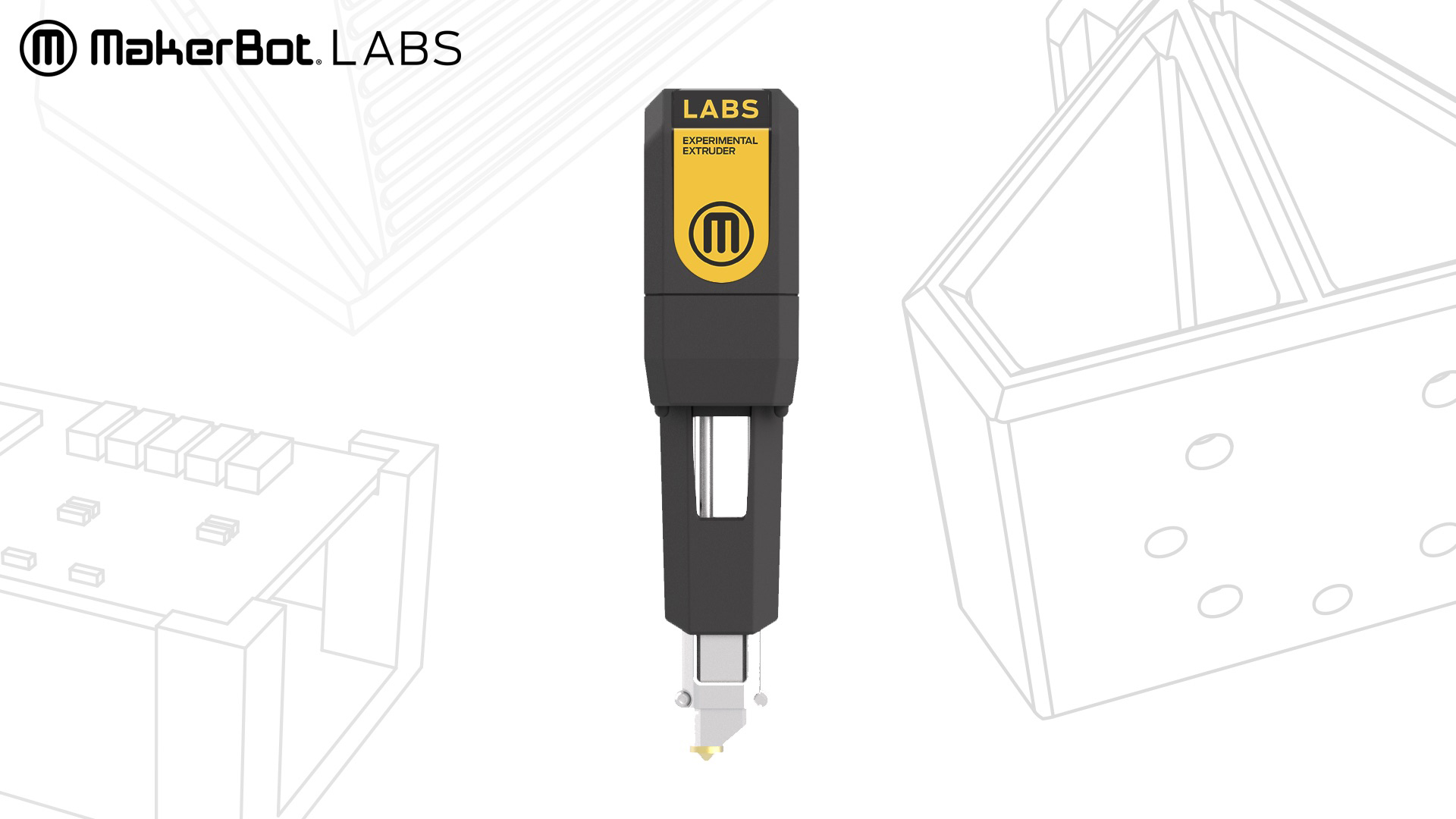

MakerBot LABS Experimental Extruder. Photo via MakerBot.

The METHOD material development program

The METHOD Materials Development Program focuses on the qualification of materials for industrial applications. The company develops through Jabil Engineered Materials Jabil PETg Electrostatic Dissipative (ESD), a material for sensitive electronics. Mitsubishi Chemical focuses on D.URABIO, a bio-based technical resin with a higher chemical and scratch resistance compared to polycarbonate (PC).

The French filament manufacturer KIMYA wants to qualify KIMYA ABS CARBON, a composite material with 30% chopped carbon fiber for improved rigidity and compressive strength. The company is also developing KIMYA ABS ESD, a material filled with carbon nanotubes for lights and electronics housings and KIMYA PETG CARBON, a reinforced material with carbon fibers for excellent rigidity.

in addition, Polymaker PolyMax PC, a Filament that combines excellent strength, toughness, heat resistance and print quality Polymaker PolyMax PC-FR, afLame-resistant PC filaments (UL94V-0 / 1.5 mm) are processed. These materials are expected to open up new applications in the automotive, railroad and aerospace industries.

MakerBot LABS Experimental Extruder

The METHOD 3D printer functions a circulating heated chamber, dual performance extruder and dry-sealed material chutes. MakerBot modified the hot ends of the experimental extruder to make changing the nozzle assembly easier. It is planned to offer additional nozzle configurations soon and shortly is expected to be released in an open beta program next month.

Formnext visitors can see the MakerBot LABS Experimental Extruders in Hall 12.1, Stand F99.

Get live updates from Formnext by subscribing to this 3D printing industry newsletter. Follow us on too Twitterand how we on Facebook.

Find talent for a project or advance your career in 3D printing – get involved 3D print jobs apply and advertise.

The picture shown shows MakerBot LABS Experimental Extruders. Photo via MakerBot.