Up Market Research (...

Tag Archives: Filament

Bulked Steady Filament Nylon Market 2021 Segmentation and Evaluation by Latest Traits, consumption by Regional knowledge, Growth, Investigation, Progress by to 2025 – The Pinstripe Empire

13

Jan

Market Overview: The global Bulked Continuous Filament Nylon market size is expected to grow in the forecast period ...

3ders.org – PolyMaker’s PC-Plus filament robust sufficient to carry 240 kg, now obtainable with out BuildTak

12

Jan

February 10, 2016 | From Alec

New Military Multi-Polymer Filament Tech Turns Low-Price 3D Printers Into Excessive-Tech Producers

12

Jan

By US Army Research Laboratory

April 27, 2020Army researchers are turning low-cost printers into high-tech manufacturing facilities ...

World Industrial Filament Market 2020 Dimension Share Upcoming Developments Segmentation And Forecast To 2025 – Murphy’s Hockey Regulation

12

Jan

The global Industrial Filament Market study focuses on insights into market growth, latest developments, industrial analy...

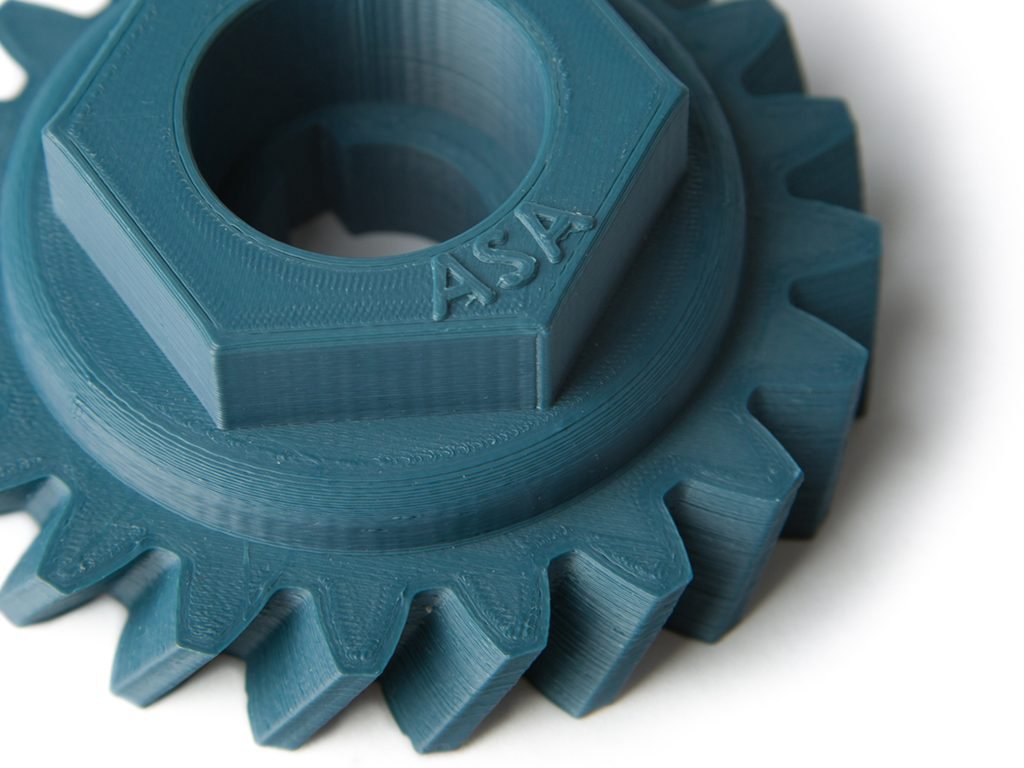

Fillamentum launches ASA 3D printer filament made for extra than simply the outside

11

Jan

Popular brand for 3D printer materials Filamentum has launched three new shades of its ASA Extrafill filament for FFF / FDM. Notin...

India imposes anti-dumping responsibility on nylon filament yarn import from Vietnam, EU

11

Jan

On the recommendation of the DGTR investigation arm of the Ministry of Commerce, India has introduced an anti-dumping duty of up t...

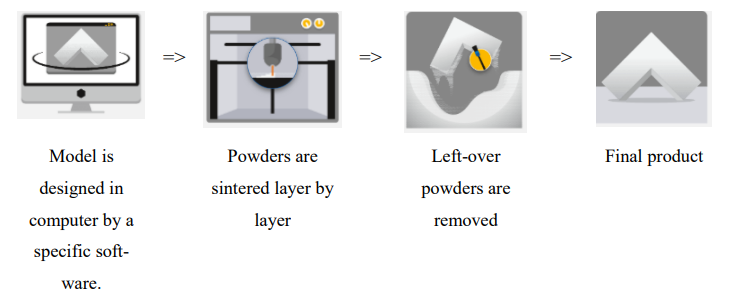

Recycling Multi Jet Fusion PA 12 Powder Into Filament – 3DPrint.com

11

Jan

Scheme of powder bed fusion processing

In a recent research...

Vietnam nylon filament yarn faces stiff Indian duties

11

Jan

By Dang Khoa August 10, 2018 | 7:12 pm GMT + 7India is considering imposing anti-dumping duties on nylon filament yarn imp...