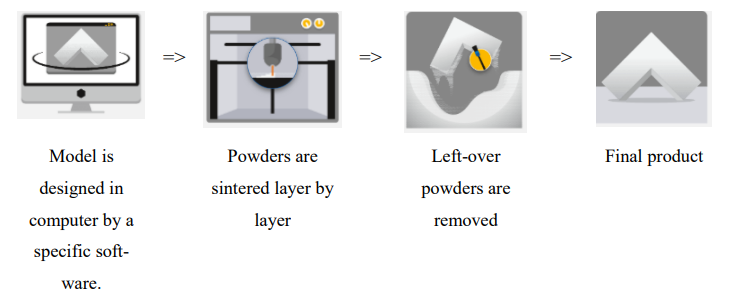

Scheme of powder bed fusion processing

In a recent research project supported by 3DTech, PhD student Dung Ha was offered a thesis to investigate the reuse of nylon PA12 powder from the 3D printing manufacturing of Multi Jet Fusion (MJF). The author’s results were detailed in the recently published dissertation “A Study on the Recycling of Polyamide-12 Waste Powder into 3D Printing Filaments”. While the idea of recycling 3D materials isn’t exactly new, Dung Ha is also exploring how fine powders can be safely handled and then made into filaments.

Nylon Polyamide 12 (PA12) is chosen by many users because it is both robust, flexible and offers high performance when printing with strong layer adhesion. Dung Ha sees PA12 as worthy of study and recycling due to its exceptional properties, but also points out that working with this material poses particular challenges due to problems with loss of integrity after processing and the tendency to absorb water. Because the author is heavily focused on laboratory work, safety is a top priority and is a comprehensive part of this study. The real issue, however, is how the powder can be recycled and reused as a 3D printing filament.

PA12 is one of the most widely used materials in 3D printing, especially for researchers and engineers. The advantages of this 3D printing powder include:

- Chemical resistance

- Water resistance

- Strong mechanical properties

- Resistance to stress cracks

- Self-supporting for end products

This powder is suitable for use in a wide variety of different applications including rapid prototyping, medical modeling, and more, and can be overall enhanced with a variety of different additives such as carbon, glass, or aluminum. 3DTech uses PA12 for its 3D printed products, typically around 55 to 60 µm in particle size, and they contributed the waste product used in the study.

Technical Property (a) and general property of PA12

Powder waste that was collected manually consisted of combined powders from various bed printer positions and was stored in three plastic boxes which were sealed and kept in the Arcada laboratory.

Sealed powder boxes in the Arcada laboratory.

“Because PA12 powder belongs to the microparticle group in this study and is based on the safety data sheet for PA12 powder, the explosion of fine powder and the health effects of fine powder by inhalation will receive a lot of attention in this work,” said Dung Ha.

The most common cause of a dust cloud explosion is usually a spark that forms somewhere in the laboratory. In some cases, explosions can occur, especially when there is a combination of dust and air that are considered dangerous due to intense concentrations. This tends to occur with finer particle sizes.

Safety needs to be considered, and while flammability is an issue, emissions are often called into question with 3D printing too. Users can breathe fine particles easily, which is a health risk – especially due to the smaller particles:

“Because they can go deep into the lungs; They can offer a chance for chemical absorption in the blood along with physical interaction with it [the] Respiratory system, ”explains Dung Ha.

Several other studies on particulate matter and emissions have been carried out in recent years, e.g. B. Specific tests on indoor air quality and the study of emissions as a whole. The author goes into more detail than usual here on how users can prevent exposure from affecting them or injuring them in an unfortunate explosion. Proper handling procedures must be followed, along with wearing appropriate protective equipment such as goggles, lab coats, masks, and following measures such as washing all areas that come in contact with powder and avoiding eating or drinking in the lab.

Colors of virgin material (left) and waste powder (right) from 3DTech Company.

The chemical degradation and oxidation of PA12 powder in the unmelted state is a problem, and as Dung Ha points out, the time and heat of [the] Print bed near the melting point increases the molecular weight of PA12 powder, which decreases the viscosity of PA12 powder. The oxidation also causes the white powder to turn both yellow and brown, and waste powder needs improvement. To combat degradation and discoloration, other researchers previously used tungsten carbide (WC) as an additive.

Oxidation in an HP MJF printed pail

To produce filaments from the recycled materials, the researcher used a 1.75 mm nozzle with a constant temperature setting of 180 degrees Celsius. There were some challenges in experimenting and adjusting the toilet additive helped; However, the researcher concluded that it may simply not be possible to make a “high-strength 3D product” from a high-strength filament. Dung Ha recommends that when developing filaments, users should consider the performance of the FDM 3D printing system being used.

Overall, the author concluded that recycled filaments were a success, resulting in good tensile strength and modulus. The filament also worked successfully in his MakerBot Replicator 2.0 without clogging.

3D printing has opened doors for so many designers and engineers around the world and has sparked an almost global euphoria of enduring creativity. But almost as soon as the fun started, users began to worry about issues related to safety, emissions, and what to do with 3D printing waste – including recycling methods, from filaments to plastics. More information on recycling polyamide 12 powder into filaments can be found here. What do you think of this news? Let us know your thoughts! Join the discussion on this and other 3D printing topics on 3DPrintBoard.com.

Filament processing by fila rudder

[Source / Images: ‘A Study on Recycling of Waste Polyamide 12 Powder into 3D Printing Filaments’]