Popular brand for 3D printer materials Filamentum has launched three new shades of its ASA Extrafill filament for FFF / FDM. Noting that more and more users are switching from ABS to higher-resistance thermoplastics, the company explains, “ASA is becoming increasingly popular with designers and it’s because of its properties. ASA is ideally suited for outdoor use, but is also ideal for prototyping. “

Fillamentum 3D printer materials

Fillamentum is headquartered in the Czech Republic and is an established supplier of high quality 3D printer filaments. The range of materials currently includes 9 different polymer qualities, from PLA Premium and PLA Crystal Clear to ABS Extrafill and high-tech CPE.

Before the last version, Fillamentum ASA Extrafill was available in nine different colors including Metallic Gray, Natural, Sky Blue, Green Grass, and Traffic Yellow. The three new shades that have been added look significantly more industrial, namely white aluminum, gray-blue and anthracite-gray.

In terms of strength and properties, ASS is often compared to conventional ABS filaments. In fact, ASA was developed as an alternative to its high-strength cousin to improve ABS’s resistance to weather and UV light.

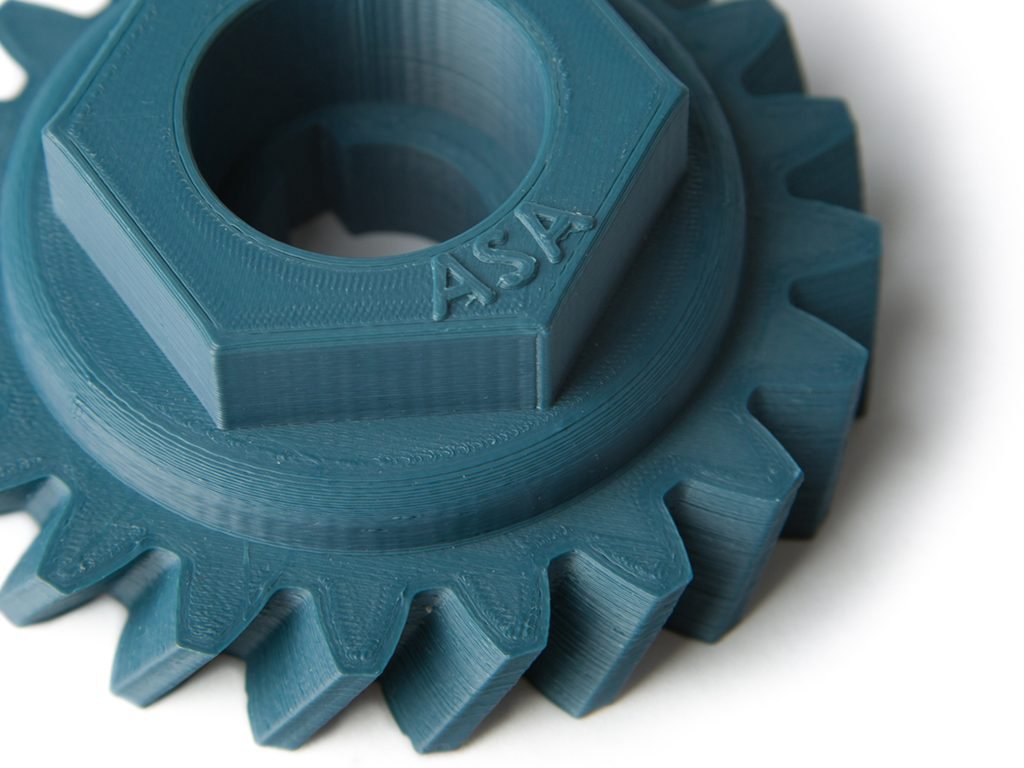

A gear 3D printed with ASA Extrafill Gray Blue. Photo via Fillamentum

ASA versus ABS

How exactly do the two materials compare? The tensile strength of ASA Extrafill is 40 MPa with an elongation at break of 35% and a flexural strength of 62 MPa.

In comparison, ABS Extrafill has a slightly lower tensile strength of 32/39 MPa (depending on the test conditions), an elongation at break of 20% and a flexural strength of 60 MPa.

The thermal properties of ASS are also superior to ABS. Fillamentum ASA Extrafill typically distorts at temperatures of 86/96 ºC (1.8) MPa Verse 0.45 MPa (test conditions), while ABS has a heat dissipation temperature of up to 81 ºC. Therefore, ASA’s printing temperature is typically higher than ABS, which is recommended in the range of 240-255 ° C, compared to the ABS recommended range of 220-240 ° C.

When printing, ASA Extrafill has strong interlayer adhesion, less comparable deformation than ABS and less styrene emissions. It is also a recyclable material.

Stack of ASA Extrafill 3D printed gears. Photo via Fillamentum

Stack of ASA Extrafill 3D printed gears. Photo via Fillamentum

A recommended material for prototyping

Like ABS, ASA is not recommended for food contact or medical applications, but it is better suitability for products for outdoor use, and has a higher stiffness than comparable ABS strains. The RoHS-compliant material is an ideal prototype for electrical components. The wide range of ASA colors that Fillamentum offers also helps to better serve these applications, giving designers the ability to create vibrant concepts that approximate the appearance of an end product.

So far, the ASA Extrafill filament series from Fillamentum has received a lot of positive support from its customers. Tom Jackson, the maker of Filament Frenzy channel on YouTube, says, “I haven’t had good results with any ABS and have heard that ASA has some of the same properties. Then I got the chance to try Fillamentum ASA and this product is excellent.

“Combine these breathtaking properties with amazing colors and you have a special material: practical yet beautiful, Fillamentum has done it again.”

ASA Extrafill is currently available directly from Filamentum In 1.75 and 2.85 mm, 750 g spools online and 2.5 kg spools on request. You can check out the new one White aluminum, Gray blue and Anthracite gray Shadow here.

Nominate your materials company of the year and more in the 2019 3D Printing Industry Awards. Subscribe to our free Newsletter, Follow us on Twitter and how we on Facebook for the latest news updates. Find 3D print jobs now near you.

The picture shown shows 3D printed gears made from Fillamentum ASA. Photo via Fillamentum