Dutch filament manufacturer 3devo has released an improved flushing material for its machines, the DevoClean Midtemp EZ.

With the new connection from 3devo, users can clean their filament manufacturers more effectively between jobs, prevent cross-contamination and ensure the durability of the system. The EZ also outperforms the previous DevoClean range, offering users a faster, more efficient and more odorless method of rinsing after testing materials.

3devo has launched a new mixture that is optimized for rinsing the extrusion cylinders within the current range of filament manufacturers (see picture). Image via 3devo.

Maintenance of filament manufacturers for 3D printing

Founded in 2016, 3devo manufactures and markets machines that allow users to create their own 3D printing filaments. Since its inception, the company has built a product portfolio around its systems that includes training, testing, and follow-up services that customers can use to optimize their manufacturer’s performance.

With its first machines, the NEXT 1.0 and Advanced ExtruderThe company was aimed at two specific target groups. While the NEXT 1.0 was aimed at hobbyists and enthusiasts, the Advanced was designed for researchers or small businesses, but both allowed users to recycle unwanted prints, resulting in interesting combinations of materials.

Building on this eco-friendly theme, 3devo later released its SHR3D IT granulatorthat was able to recycle 3D printed plastics into reusable materials. The system produced granules that could either be used in 3D printers that work with pelletized raw material or extruded into a wire thread in NEXT 1.0.

Since then, the company has launched its AIRID polymer dryer to speed up the filament production process, as well as a range of additional services. With the release of the new DevoClean product range, 3devo now offers its users an improved cleaning material with which they can optimize their production workflow.

Midtemp EZ material from 3devo

The new connection from 3devo is designed to prevent contamination from occurring when materials are exchanged during the filament manufacturing process. The wide heat range of the material of 180-420 ° C allows users to clean at the same temperature level as when extruding the machine and to remove possible residues.

The company also offers ‘Mid Temp’ and ‘Max Temp’ variants that allow customers to choose the version that best suits their thermal needs. Once deployed, the Midtemp EZ now works more efficiently than before, using 30% less material to flush and wasting 200% less transitioning between tasks.

Since the new material from 3devo is grafted with special grinding additives, it also does not scratch the inside of the extruder housing of the machine and thus improves its durability. Another advantage of the EZ is a reduced “plastic smell” during washing. In addition, permanent colors can be removed, avoiding potential processing delays.

Update the flushing process

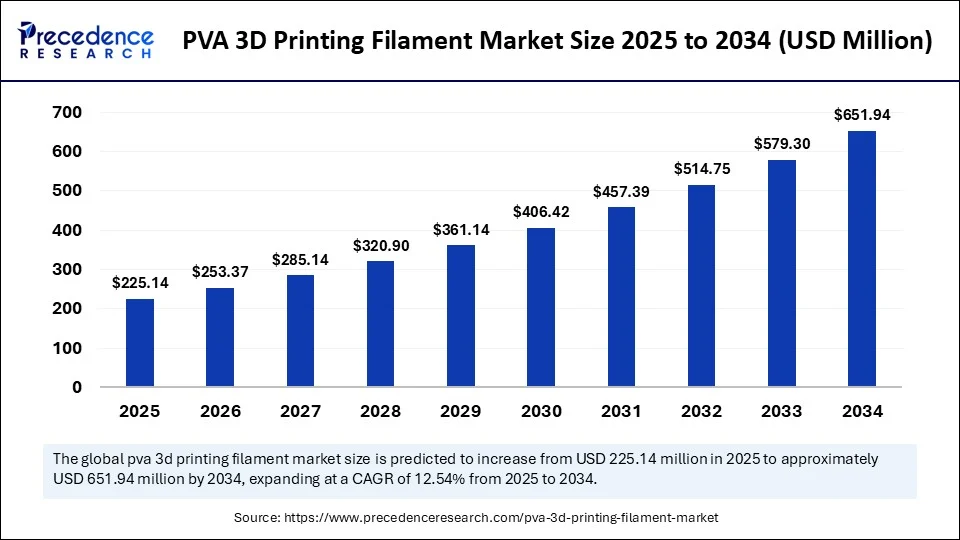

As the compatibility of 3D printers with bespoke filaments continues to grow, the demand for new products that optimize the performance of filament making machines has increased at the same time.

In the past 3devo tried to identify them optimal extrusion temperature for PEEKand studied the manufacture of piezoelectric powders. The Japanese chemical company VELOX now has its ASACLEAN detergentthat aim to offer users an inexpensive, residue-reduced alternative.

Canada-based OEM Dyze design has released his new one Typhoon print head for large 3D printers. The extended part allows users to assign a heat core to each material type, which may speed up the cleaning and rinsing process.

Don’t forget to subscribe to stay up to date with the latest 3D printing news 3D printing industry newsletter or follow us further Twitter or like our site Facebook.

Are you looking for a job in the additive manufacturing industry? visit 3D print jobs for a selection of roles in the industry.

The picture shown shows one of the filament manufacturers from 3devo. Image via 3devo.