Italian 3D printer manufacturer ROBOY has introduced a new amorphous thermoplastic polyimide filament for its ARGO production 3D printer. N.amed EXTEM ™ AMHH811F, the material was produced in cooperation with the global chemical manufacturer SABIC. The new filament is very heat-resistant and flame-retardant and in some cases is intended to replace metals in extreme applications. Keith Cox, SABIC Senior Business Manager for Additive Manufacturing, commented:

“To enable customers to print high quality parts for a range of demanding high heat applications, SABIC and ROBOZE worked closely to optimize the printing parameters and ensure UL detection for EXTEM parts printed on the ROBOZE ARGO 3D printer . “

3D printed part with EXTEM AMHH811F filament. Photo via ROBOZE.

3D printing materials at SABIC

Founded in 1976, SABIC is a global diversified chemical manufacturer headquartered in Riyadh, Saudi Arabia. The company operates in key end markets such as construction, medical devices, packaging, agro-nutrients, electrics and electronics, transportation, and clean energy in over 50 countries.

It has evolved into a Number of materials for additive manufacturing. Most recently the company started a Tear-off material for FFF 3D printers. In 2018, SABIC also released three new ones FFF filaments for end-use and prototyping purposes.

ROBOZE has worked with SABIC on a previous opportunity to create a FFF polycarbonate filament for the 3D printer platform from ROBOZE in 2018. The material is characterized by high impact resistance and ductility at low temperatures (down to -30 ° C).

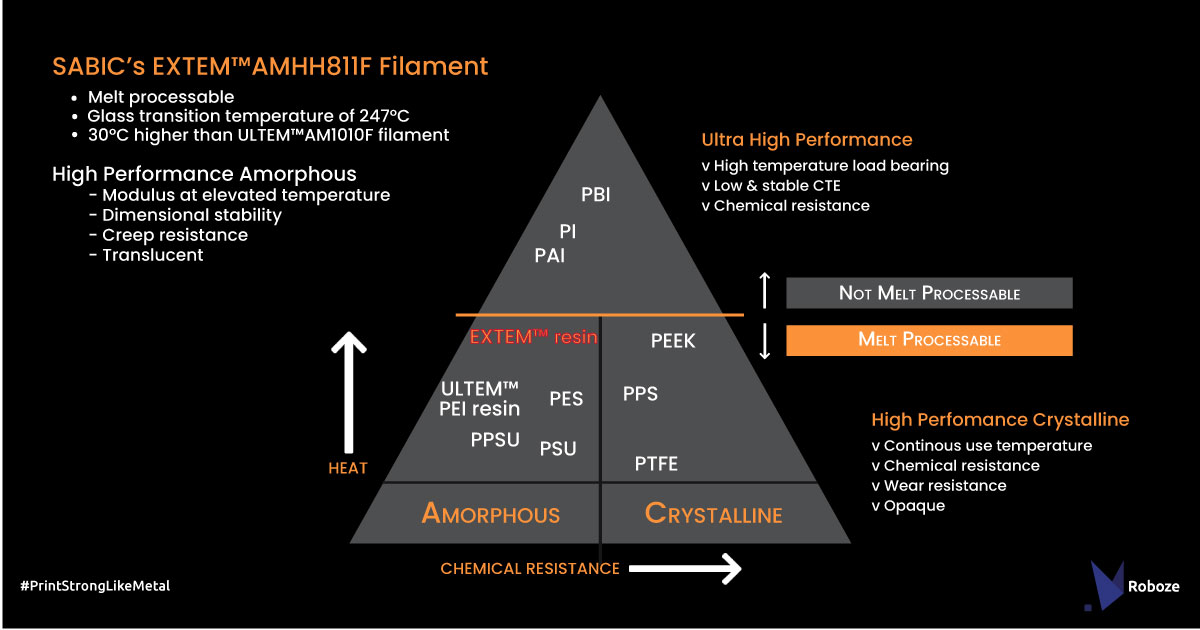

Graphic showing the properties of EXTEM AMHH811F. Image via ROBOZE.

Graphic showing the properties of EXTEM AMHH811F. Image via ROBOZE.

Replacing metals with heat-resistant 3D printing filaments

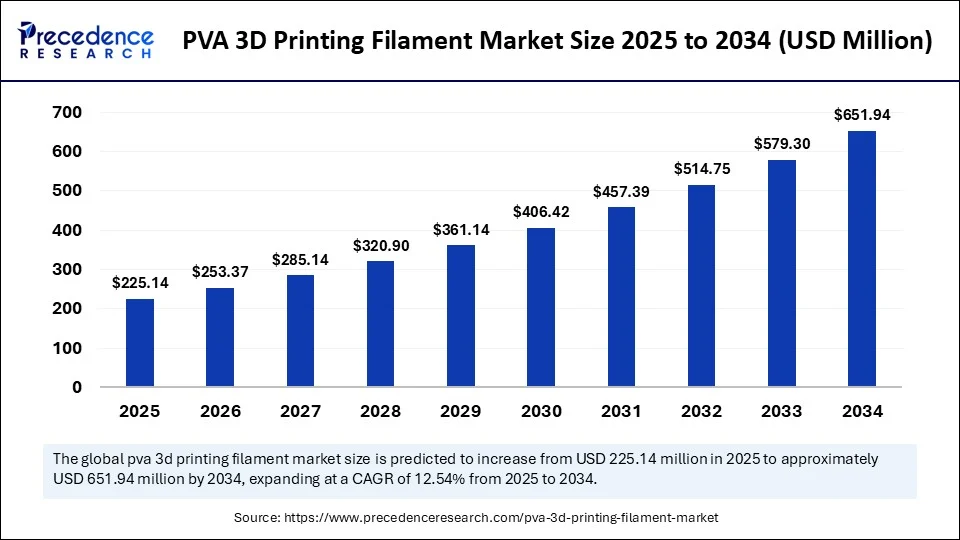

SABIC’s EXTEM AMHH811F filament is now back in partnership with ROBOZE ARGO 3D printers. The ARGO 500 presented at Formnext 2017 has a print volume of 500 x 500 x 500 mm and is designed for production in the aerospace, automotive and industrial sectors.

The EXTEM AMHH811F material is a semi-transparent thermoplastic polyimide (TPI). It is characterized by its heat resistance with a heat dissipation of up to 230 ° C and the ability to maintain its mechanical strength at high temperatures. It also has a glass transition temperature (Tg) of 247 ° C. In addition, the material is flame retardant, has good chemical and ignition resistance, as well as excellent dimensional stability and easy processability.

In addition, the EXTEM filament achieved that Blue card Recognition of the, a global security advisory and certification firm based in Illinois, with V0-075 certification for 0.75mm thick samples printed by the ROBOY ARGO System. UL’s Blue Card program was launched in early 2019 to ensure further product transparency and quality assurance for 3D printing materials.

Because of this, ROBOZE believes the material can meet the requirements of high performance metal products such as thermal and acoustic shields, housings for electronic components, and sensors for electric vehicles. Alessio Lorusso, CEO and founder of ROBOZE, sums up: “With the 3D printers from ROBOZE ARGO Production and the new EXTEM ™ AMHH811F filament, we can increase the possibilities for metal replacement. I am sure that all of this will guarantee users great benefits in terms of speed and productivity. “

ROBOZE will present the first 3D printed parts from EXTEM AMHH811F during the premiere Formnext 2019at booth 121-C61.

Subscribe to the 3D printing industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us Twitter and continue to like us Facebook.

Looking for a career in additive manufacturing? visit 3D print jobs for a selection of roles in the industry.

The picture shown shows a 3D printed part with EXTEM AMHH811F filament. Photo via ROBOZE.