LONDON--(BUSINESS WIRE) - According to the latest market study published by Technavio, the global wood-plastic composite (WPC)...

Tag Archives: Wood

3ders.org – Artist creates amazingly lifelike tree sculpture utilizing 3D printing pen & wooden filament

01

Jan

March 5, 2018 | From Tess

There is no question about that 3D printing pens can be used to create some pretty amazing ...

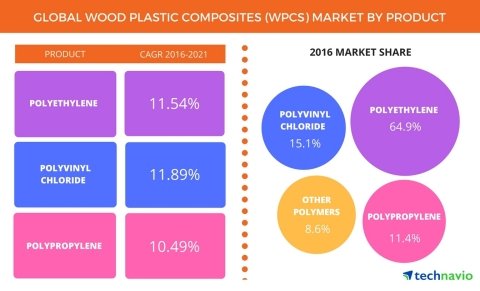

Progress in Housing and Building Industries Will Drive the Wooden Plastic Composites Market, Says Technavio

24

Dec

LONDON--(BUSINESS WIRE) - According to the latest market study published by Technavio, the global wood-plastic composite (WPC)...

Researchers use industrial wood-waste to make FDM/FFF wooden filament

23

Dec

Scientists at Michigan Technology University in Houghton have successfully created 3D printable wood filaments from furniture wood was...

Wooden Filament: The Fundamentals & Finest Wooden PLA Manufacturers – All 3DP

17

Dec

Wood Filament: The Basics and Best Wood PLA Brands All 3DP