The choice of materials in the 3D printing area is being expa...

Tag Archives: Robotics

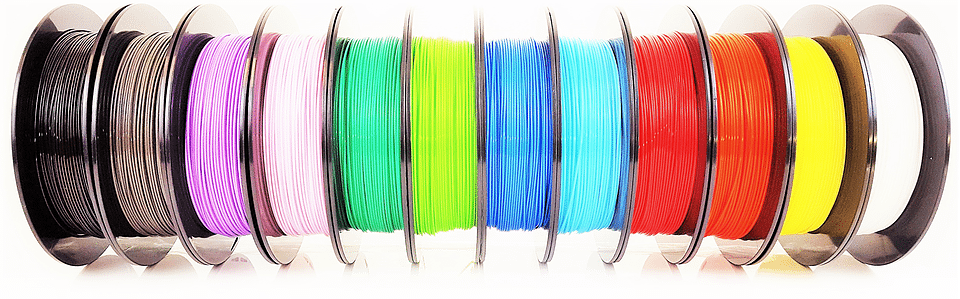

AIO Robotics releases new PLA filament

20

Dec

The PLA filament market has been quite competitive as PLA filaments could probably be the most basic material for 3D printing. Althou...