While my humble family has not yet been struck by a disaster,...

Tag Archives: Printing

3D Printing Filament Market Measurement 2021 Evaluation, Development, Distributors, Drivers, Challenges With Forecast To 2027 – NeighborWebSJ

22

Jan

Request download sample Ask for a discount Company Profile Price and Purchase OptionsVerified Market Research, the fastest growing ...

3D Printing Filament Tools Market Development Set to Surge Considerably throughout 2020-2026

19

Jan

The 3D printing filament device market growth will increase significantly in the period 2020-2026Date: 2020-12-29...

PLA Filament for 3D Printing Market 2021 Trade- Rising Development, Prime Gamers, Income Insights to 2027 – Splash Radio Wales

19

Jan

Request download sample Ask for a discount company profileNew Jersey, United States, - PLA Filament for 3D Printing market report of...

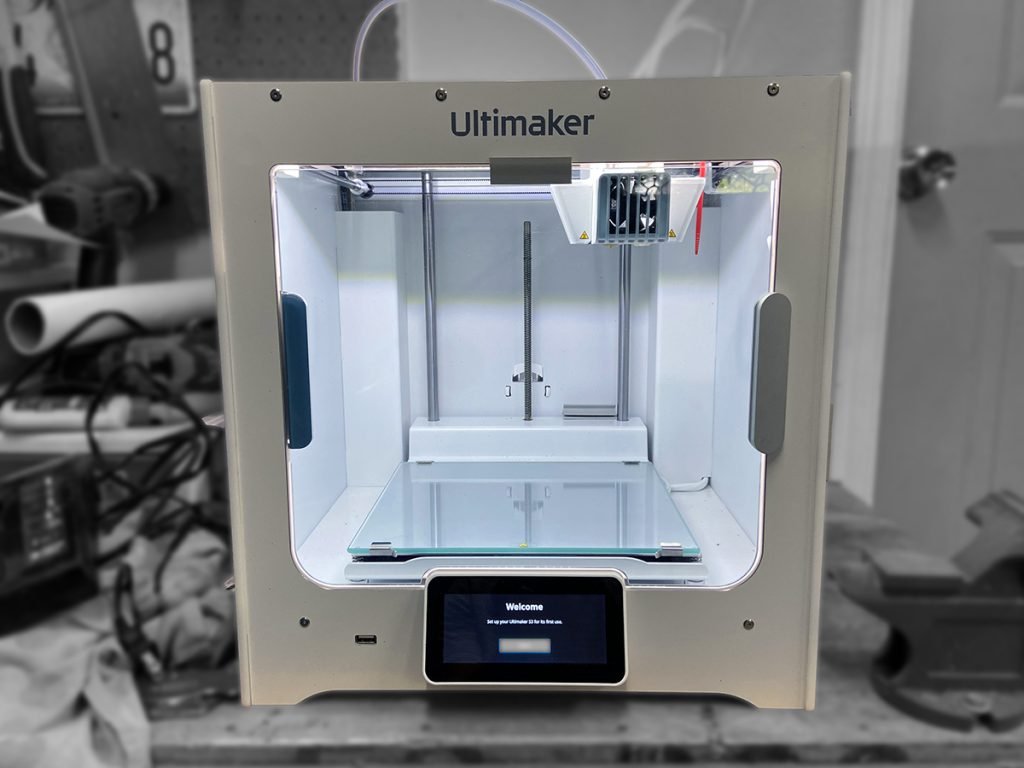

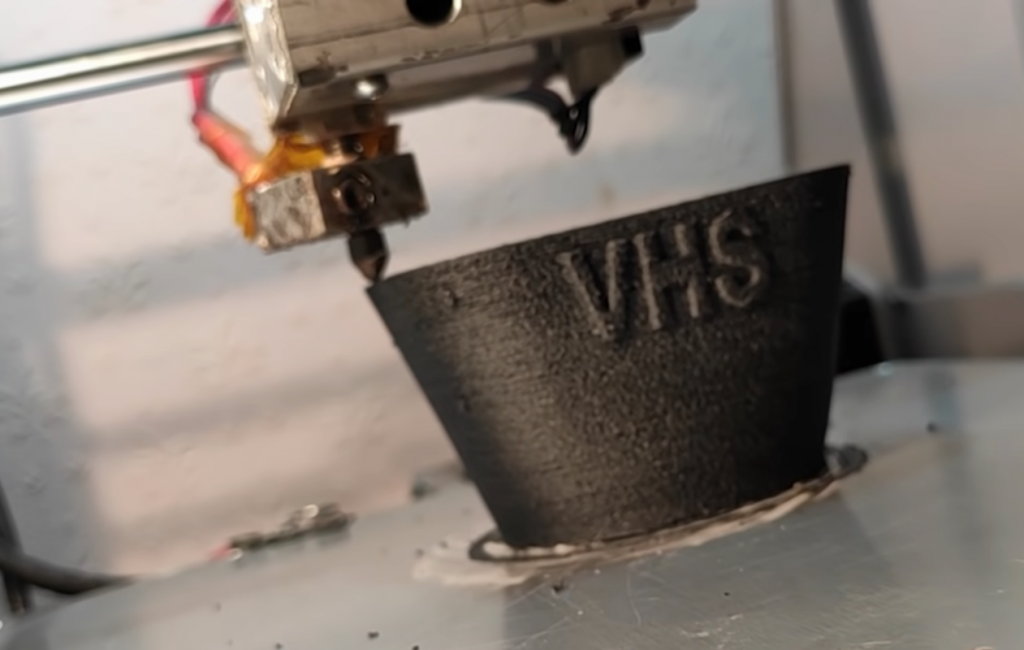

3D Printing With VHS Tape Filament

19

Jan

When you have a pile of old VHS tapes in your attic or basement that you know you will never watch again, either be...

3ders.org – Voodoo Manufacturing provides glorious versatile TPU plastic filament to their 3D printing companies

09

Jan

June 16, 2016 | From Andre

When it comes to the desktop 3D printer market, there was a time when your material choices wer...

M. Holland now distributing BASF Ultrafuse 316L steel composite filament » 3D Printing Media Community

09

Jan

M. Holland Company, a distributor of thermoplastic resin materials, has announced an expanded sales partnership with BASF 3D Printing ...

Canadian Startup is Turning Meals Waste into Biodegradable, Plastic 3D Printing Filament – 3DPrint.com

09

Jan

3D printing is often used in sustainability efforts, such as...