The Nylon 6 Filament Yarn Market report examines the short and medium term economic and profitability prospects for the Nylon 6 ...

Tag Archives: Filament

3ders.org – colorFabb_HT filament revealed, good for sturdy and temperature resistant 3D prints

09

Jan

March 1, 2016 | From Alec

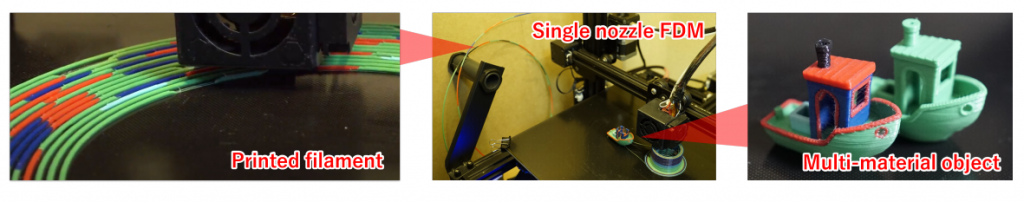

Programmable Filament: Multicolor & Multimaterial 3D Printing with No {Hardware} Upgrades – 3DPrint.com

09

Jan

Most of us are still excited about the opportunity to toss as...

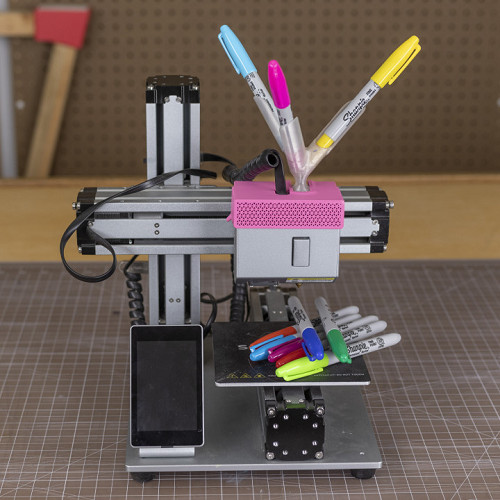

3D Printed Sharpie Mount Provides a Pop of Coloration to White Filament – 3DPrint.com

08

Jan

Want to add multiple colors to your prints, but can only affo...

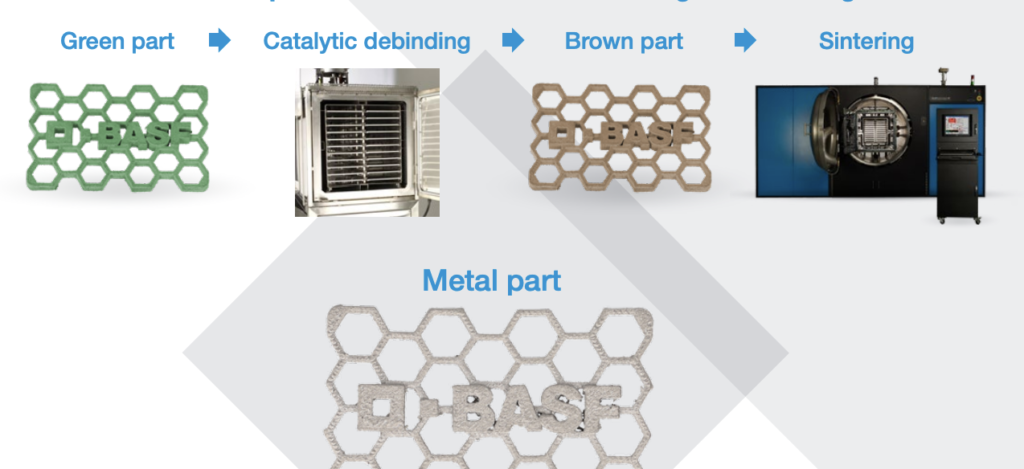

BASF Launches 17-Four Stainless Metal Metallic 3D Printing Filament for FDM Printers – 3DPrint.com

08

Jan

BASF's Forward AM unit has launched 17-4 PH metal filaments f...

Pla 3D Printer Filament Market Measurement 2021, Progress Issue, Key Gamers, Regional Demand, Traits and Forecast To 2027 – NeighborWebSJ

08

Jan

Credible Markets has added new key research reports covering the Pla 3D Printer Filament Industry market. The study aims to provide ...

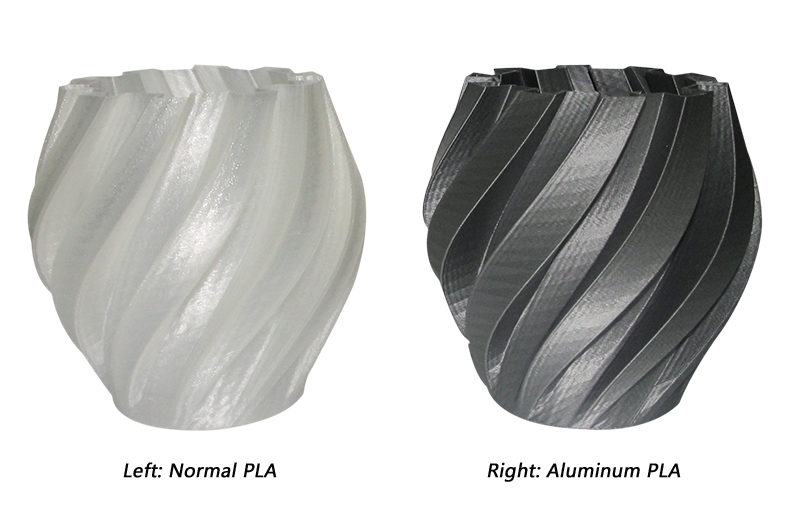

RepRapper Tech Providing Aluminum PLA 3D Printing Filament – 3DPrint.com

08

Jan

Material innovations for 3D printing are getting hot and heav...

3ders.org – Polymaker unveils PC-Max, their strongest 3D printing filament for load-bearing components

07

Jan

May 16, 2016 | From Alec

SABIC unveils new portfolio of high-performance filament grades for FDM 3D printing

07

Jan

SABIC, a thermoplastic technology company, presented a new portfolio of high-performance filament grades for FDM 3D print...