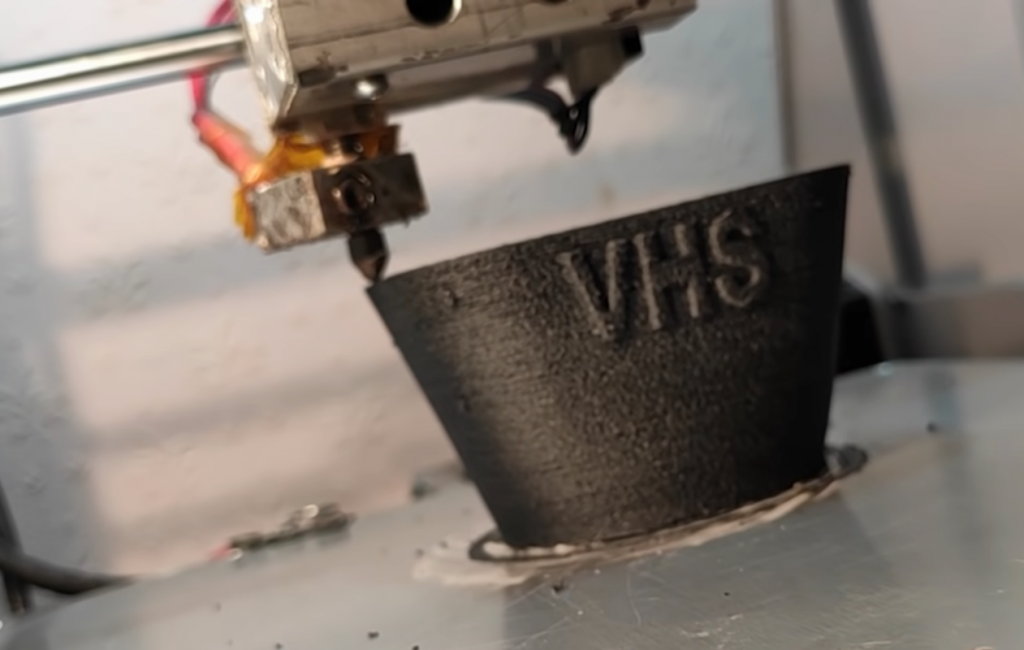

When you have a pile of old VHS tapes in your attic or basement that you know you will never watch again, either be...

Tag Archives: Filament

PLA 3D Printer Filament Market Newest Developments, Latest Developments, Future Demand and Forecast and Key Gamers – ProtoParadigm LLC MakerBot Industries, LLC – KSU

19

Jan

PLA 3D Printer Filaments Market Review: Introduction

Decisive Markets Insights publishes detailed report on the global mark...

International Nylon Filament Market (2020-2026) | Newest COVID19 Impression Evaluation | Know About Model Gamers: Milliken & Firm, Hyosung, Efficiency Fibers, Kolon Industries, Kordarna Plus A.S., and so on.

16

Jan

The report with the title Nylon Filament Market: Size, trends and forecasts (2020-2025) "Provides an in-depth analysis of the Nylon ...

3ders.org – Innofil3D and Polyscope’s new ABS Fusion+ filament can be utilized with water-soluble helps

16

Jan

September 14, 2017 | From Tess

The Dutch company Innofil3D has launched a new ABS 3D printing filament in collaboration wi...

Nylon Filament Market 2020 | Know the Newest COVID19 Affect Evaluation And Methods of Key Gamers: Milliken & Firm, Hyosung, Efficiency Fibers, Kolon Industries, Kordarna Plus A.S., and so on.

16

Jan

The Nylon Filaments market research report offers various layers of analysis such as industry analysis (industry trends), market...

Newest Replace 2020: Nylon Filament Market by COVID19 Affect Evaluation And High Producers: Milliken & Firm, Hyosung, Efficiency Fibers, Kolon Industries, Kordarna Plus A.S., and many others.

15

Jan

Global Nylon Filament Industry Research Report provides in-depth insights into all key parameters including development tr...

3D Printering: XT-CF20 Carbon Fiber Filament Assessment

14

Jan

ColorFabb’s XT-CF20 is one of the more exotic filaments for adventurous 3D printerers to get their hands on. This PETG based m...

3ders.org – MatterHackers stress exams its hybrid NylonX 3D printer filament with spectacular outcomes

14

Jan

October 14, 2016 | From Andre