We're not sure what a typical weekend is The house is like, but we can probably assume that any activity will at least be acco...

Tag Archives: Filament

PCTG Filament Has Fascinating Properties

25

Mar

Early 3D printers used ABS, but bad fumes and warps made most people go to PLA. However, PETG has many of the great propertie...

3D Print in A number of Colours with a Single Extruder with the Ingenious Stick Filament

24

Mar

The latest craze in the 3D printing hobbyist today is multicolor printing. However, this requires printers with multiple extruder...

PLA 3D Printer Filament Market 2021 | Covid19 Influence Evaluation | Demand, Value Buildings, Newest developments, and Forecasts to 2026

24

Mar

A new business intelligence report from Qurate Research entitled "Global PLA 3D Printer Filaments Market Research Report 2021" th...

Impression of COVID-19 on 3D Printing Filament Market to Report Important Income Progress Throughout the Forecast Interval 2021-2025 – The Bisouv Community

24

Mar

Outlook for the 3D printing filament industry in 2021

The outbreak of Covid-19 in the world market has left companies uncertain about ...

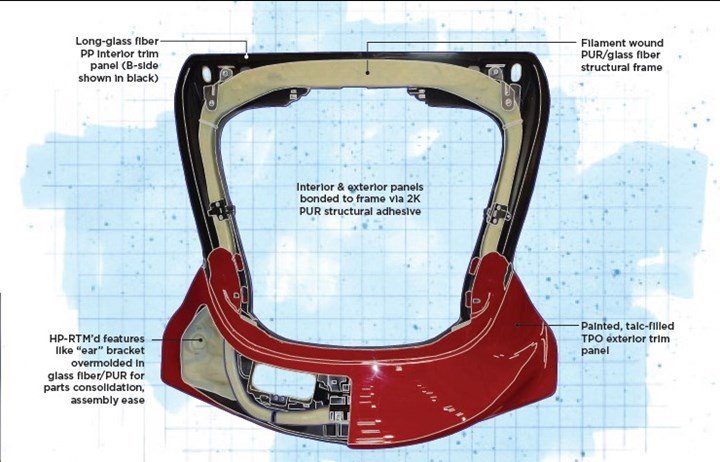

Liftgate design places modified filament winding to the check

24

Mar

Illustriert von Susan KrausKfz-Heckklappen oder Heckklappentüren wechseln seit Jahrzehnten langsam von Metallen zu...

Victrex Launches Victrex AM PAEK Filament Optimized For Additive Manufacturing

24

Mar

INTAMSYS is the first reseller of the new AM PAEK filament from Victrex for 3D printing

Above: Various parts printed with VICTREX AM ...

Bulked Steady Filament Nylon Market in United States – The Bisouv Community

23

Mar

"

Get sample report

Bulked Continuous Filament Nylon Market Research Report is the n...

Industrial filament Market 2021 Current Scope, Rising Reputation and Rising Traits within the Market: – Cabell Customary

23

Mar

Acquire Market Research has published a scholarly market assessment entitled Industrial Filament Market. Learning about provides...