Flex Your Power TPE vs TPU Flexible Filament: The Differences All 3DP

3D Filament Blog

What Is the Strongest 3D Printer Filament? – All 3DP

10

Dec

What is the strongest 3D printer filament? All 3DP

Source Link

...

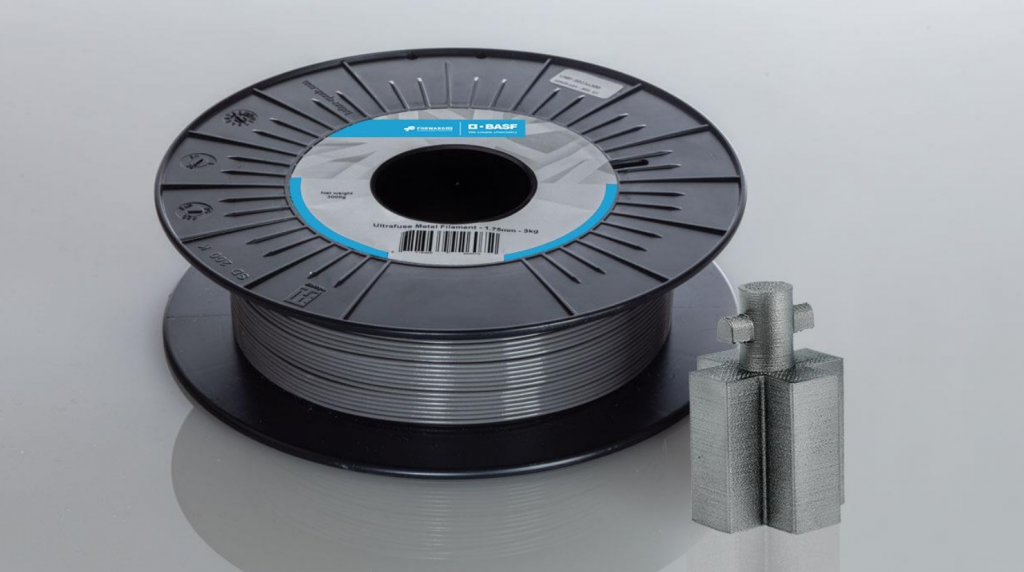

BASF’s Ahead AM launches new Ultrafuse 17-Four PH stainless-steel filament for tooling purposes

10

Dec

Forward AM, a 3D printing arm for a chemical company BASFhas started his new one Ultrafuse 17-4 PH Metal thread.

The stainless stee...

6 days in the past 3D Printer Filament Storage: 10 Methods to Retailer Filament – All 3DP

10

Dec

6 Days Ago 3D Printer Filament Storing: 10 Ways To Store Filament All 3DP

Recycled 3D Printer Filament: The Fundamentals & Finest Manufacturers – All 3DP

10

Dec

Recycled 3D Printer Filament: The Basics and Best Brands All 3DP

Recycling second printers into 3d printing filament

10

Dec

These are the company's first in-house developed products, established in Japan to achieve...

World Industrial Filament Market Progress Graph To Exhibit Inclination In the direction of Optimistic Axis By 2026 – The Courier

04

Dec

There are millions of them around the world waiting to catch up on some of the latest important information that is being cir...

PLA 3D Printer Filament Market Entry Methods, Countermeasures, Financial Impression And Quantum Sensors Advertising Channels To 2027

04

Dec

PLA 3D printer filament market

IndustryGrowthInsights, 04122020: The research report on PLA 3D Printer Filament Market is a thorough a...