3D Printer & Filament Black Friday 2019 Offers

Published on November 28, 2019

3D Insider is ad-supported and makes money with clicks and other opportunities.

Black Friday is back with us and it’s the perfect time to take advantage of the limited offers on 3D printers and filaments. New offers come and go as I write. I will keep this guide updated with the best deals available over the next 48 hours.

All the big brands are happening this year with some exciting savings on popular models. OK, let’s start with some of the hottest and most discounted 3D printers first:

Limited 3D printer deals for Black Friday, 2019

There are currently 10 offers that are worth considering. Follow the links for more information and to check current stock levels and any last minute extras. Good luck.

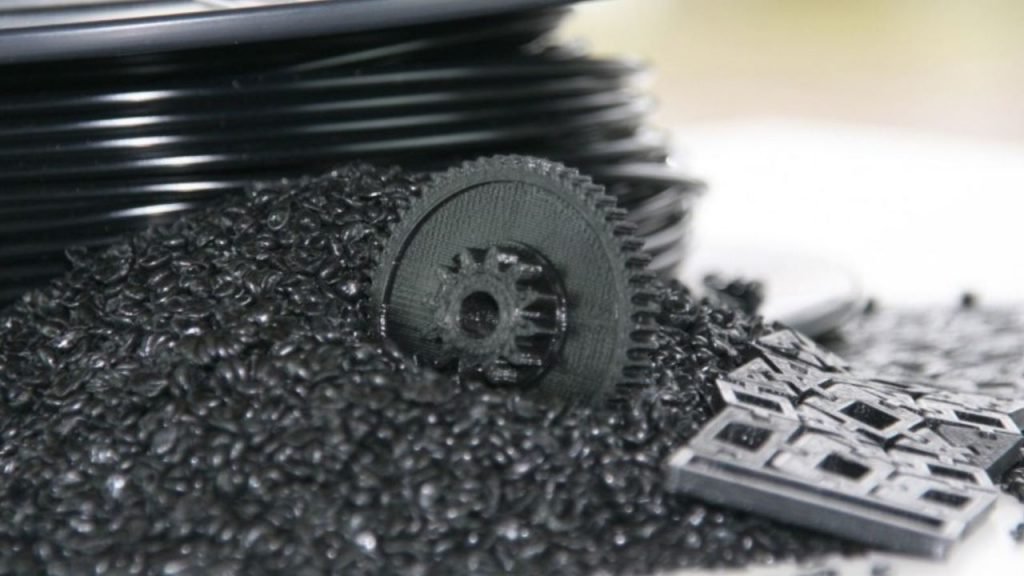

3D printer filaments for Black Friday, 2019

There can be no 3D printing without 3D filaments. The good news is that some of the best branded threads have Black Friday deals, too. Check out these short-lived filament deals below.

Discounts for 3D printer software

It’s less common to see discounts on popular 3D printing software. It happens occasionally. So keep an eye on the following two programs for the next 24 to 48 hours.

Choosing a 3D Printer Quick Tips

There are several considerations when buying a 3D printer. Only you can know what you want and what projects you are doing, but the following XX points apply to all new buyers.

No. 1 3D printer built panels

First, consider the size of the build plate. Larger build panels cost more, but are the smaller panels suitable for your projects? Make sure you answer this question before you commit. A plat that is too small for its purpose is a wasted investment.

# 2 3D printing materials

Some printers can only work with PLA. That’s fine if that’s all you need. However, imagine a device that allows you to print other filaments or those with multiple materials. There are also different surfaces, colors and textures to consider. Learn about the different thread types and what they need.

# 3 Housing & Security

Not all 3D printers have housings to protect the user from the high temperature extruder. It is also not a law to have them. However, security is essential and should always be a buying factor. Specifically, consider a housed 3D printer if you are a beginner and on budget.

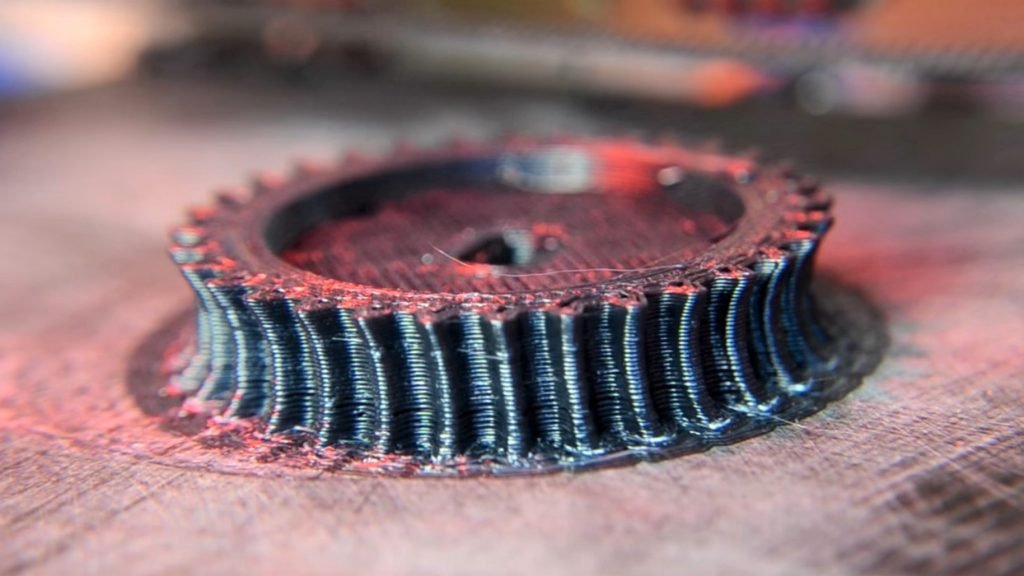

# 4 understand printer resolutions

All 3D printers print in 3D, but not all are created equal. A device’s XY resolution has more impact on print quality than anything else. This is important when you want to create models that are as smooth and detailed as possible.

Think about what to expect from a 3D printer when you first shop. What are your current and future project plans? A short list of needs and expectations is a brilliant, low-tech way to help you make better buying decisions. Finally, make sure you have adequate desk space and a ventilated area to safely operate your new machine 😉

Warning; 3D printers should never be left unattended. They can pose a fire hazard.