From the Delaware Public Archives: Filament of the Future – delawarebusinessnow.com

From the Delaware Public Archives: Filament of the Future delawarebusinessnow.com

Source Link

From the Delaware Public Archives: Filament of the Future delawarebusinessnow.com

Source Link

The Dutch filament manufacturer colorFabb has added a new filament to its constantly growing portfolio. The 3D printing material called varioShore TPU is a filament with versatile, flexible properties that is suitable for applications in the shoe and sporting goods sector due to its soft feel.

One of the most interesting things about colorFabb’s newest filament is that its flexible properties can be adjusted to achieve different degrees of hardness on land. By adjusting the print settings, it is even possible, according to the company, to integrate multiple land hardnesses into a single print.

varioShore TPU was developed by the Belfeld-based filament maker using the same technology it used to make their lightweight foaming PLA (LW-PLA) material, which was launched earlier this year. This means that the TPU material has the added benefit of being lighter than other brands – although the weight reduction isn’t as drastic as that of the PLA-based filament.

The material is also characterized by its soft feel, which makes it suitable for applications in shoes such as shoe soles or in sporting goods such as bicycle handlebars.

The new varioShore TPU from colorFabb will be available from mid-October (pre-orders begin at the beginning of October). Before that, the Dutch company will present its new material – along with many other filaments – at the Kunststoffenbeurs 2019, a leading plastics and rubber fair in the Netherlands.

There has been a fair share of material releases from the 3D printing industry over the past week. In addition to the new varioShore TPU filament from colorFabb, the German 3D printing company EOS has introduced a new flexible material in industrial quality. TPU 1301;; Desktop 3D printer maker MakerBot has a Precision ASA filament ideal for outdoor use; Markforged started Inconel 625 for its Metal X metal 3D printing platform; and 3D Systems launched several new materials for its system in Figure 4, including Figure 4 PRO-BLK 10 for digital production parts.

At the start of the game, you might think you don’t need a Division 2 printer filament, but by the time you reach the endgame, you’ll be looking for it in droves. Other craft materials in The Division 2 are pretty easy to come by, but if you don’t know how to get them, then it’s easy to miss the Division 2 printer filament. Follow this guide which covers everything you need to know about Division 2 printer filaments, including what it is and how to get it.

Tips for Division 2 | Best Division 2 skills | Best advantages of Division 2 | Division 2 Hyena Key locations | Division 2 Dark Zone Keys | How to move up quickly in Division 2 | Division 2 masks | Division 2 ivory key | Division 2 Dark Zone Guide | How to unlock the Dark Zone in Division 2 | Handicraft instructions of Division 2 | Department 2 specializations | How to unlock specializations in The Division 2 | Division 2 dyes | Division 2 mods | Division 2 map | Division 2 printer filament | Division 2 bounties | Division 2 is building | Division 2 snitch cards | Division 2 hidden side missions | Division 2 exotic | Division 2 final

Printer Filament is a superior manufacturing material in The Division 2 and is used for two things. The first is making Gear Mods; Both Protocol Gear Mods and System Gear Mods in the Crafting Bench menu require a number of printer filaments each time. The effects you get on the Gear Mods you make are completely random. So if you are looking for a specific Gear Mod there is a lot of printer filament to build up.

By the time you reach The Division 2 endgame, you’ll be able to level up your crafting bank for each world level you progress through. At the moment the highest world level in the game is four, but when the first raid starts this value should increase to five. To upgrade your craft bench, you need a lot of printer filament every time.

Obtaining printer filament is actually somewhat simple, although it is very different from other manufacturing materials like titanium and polycarbonate. To get Printer Filament in The Division 2, you’ll need to deconstruct Gear System Mods, Gear Protocol Mods, and Skill Attachments. If you deconstruct something in the Mods section of your inventory, you are essentially being rewarded with printer filament. The higher tier of the item you deconstruct will reward more printer filament. So make sure you deconstruct them and not sell them to the seller.

It’s that simple. Tag any mod that you don’t want to use as junk and deconstruct it to get valuable printer filament. After all, you have enough to upgrade your craft bank high enough for these exotic species.

As a quick tip, if you’re on the console and you’re frustrated with the L2 / LT key switching categories and marking mods as junk, move any mods you want to mark as junk to your stash first. That way you can easily scroll through the list and deconstruct it from your stash.

Are you just about to start in Division 2 and need to find some faction keys? Here’s everything we know about the Division 2 Hyena Key locations, as well as the Outcast Keys and True Sons Keys.

In the recently published study, “Investigating Closed-Loop Manufacturing with Acrylonitrile-Butadiene-Styrene (ABS) Over Generations Using Additive Manufacturing,” the authors investigate Mazher Iqbal Mohammed, Daniel Wilson, Eli Gomez-Kervin, Bin Tang, and Jinfeng Wang the effects of FFF 3D printing on acrylonitrile butadiene styrene (ABS) during multiple recycling processes.

As 3D printing grows in popularity, so does the amount of plastic discarded. And while PLA is biodegradable, ABS is a typical plastic that has no environmental issues. In this study, the researchers hoped to examine FFF systems in terms of their low power consumption, which could be a suitable path to more sustainability in manufacturing.

The researchers began using virgin ABS that went through two consecutive phases of filament extrusion and 3D printing. In this study, they used 100 percent recycled 3D printed ABS that was made into filament for reuse. This allowed them to study parameters and the potential for defects along the way.

“Studies have previously reported that changes in the melt index and mechanical properties of ABS occur after recycling through injection molding and casting,” the researchers said. “To the best of our knowledge, however, no study has investigated the impact of multiple closed-loop recycling phases using AM, where ABS quality and thermal process regimes differ from those made by molding processes.”

Virgin ABS pellets were extruded as filament and then 3D printed into parts. The researchers made sure that plastic was only used from a single source to ensure that differences are directly comparable. Granules were produced in a uniform size and separated with a sieve with a mesh size of 5 mm.

“To determine the average pellet / granule size, 20 ABS pellets or granules were randomly collected from the source batch and their longest lengths measured and averaged,” the researchers explained.

(a) Relative pressure orientations of the tensile and compression test certificates and (b) universal testing machine on which mechanical tests were carried out.

While the study focused on the use of virgin ABS, the research team also experimented with one-time, two-time recycled ABS as well as samples of 90, 80, 70, 60, 50, 40, 30, 20, and 10% virgin ABS. They assessed extrusion flow rate, 3D printing and characterization, polymer analysis and mechanical property characterization.

In some cases the “unevenness of the granules” leads to clogging as well as to “sticking” due to sharp edges. The researchers tried to stir granules during extrusion to maintain the correct filament flow. Ultimately, the research team found that the FFF 3D printer worked very well with recycled ABS and over several generations of recycling. They viewed the process as successful and as a process that could actually serve as a valid “multi-generation” manufacturing method.

(a) (i) A graph showing the change in extruded filament diameter for changes in extrusion temperature; For the sake of clarity, only results for virgin, 10% recycled, 50% recycled and 100% recycled ABS are shown. (a) (ii) Temperature differences when extruding a respective ABS mixture relative to a filament diameter of 1.75 mm. (b) (i) extrusion flow rate for different ABS blends comprising different percentages of recycled to virgin material; For the sake of clarity, only results for virgin, 10% recycled, 50% recycled and 100% recycled ABS are shown. (b) (ii) Extrusion flow rate for the various ABS blends in forming filaments with a diameter of 1.75 mm.

“FFF has arguably the greatest commercial success right now in the production of concept prototype devices by design firms or in the production of ornaments such as toys and models that generally do not have strict mechanical strength requirements. We therefore believe that using recycled ABS made from single or double recycled variants could potentially replace virgin polymer filaments in such applications, as the measured drop in mechanical strength would not affect the function of the end parts or prototypes. The researchers concluded.

“The FFF has significant potential for sustainable management of ABS plastics through their reintroduction into broader industrial manufacturing and potentially creating value from an otherwise growing burden on resource recovery sites and landfills.”

ABS is one of the most popular 3D printing materials for users of all levels, whether they are making new materials and composites, refining adhesion issues, or even creating jobs. What do you think of this news? Let us know your thoughts! Join the discussion on this and other 3D printing topics on 3DPrintBoard.com.

Compressive stress comparison for 3D printed samples printed using (a) virgin, (b) once recycled, and (c) twice recycled ABS. (d) Summary of the compressive stress for the various ABS samples printed in the two spatial orientations. (e) Summary table of results for all compression test samples.

[Source / Images: ‘Investigation of closed loop manufacturing with Acrylonitrile Butadiene Styrene (ABS) over multiple generations using Additive Manufacturing’]

Fillamentum Releases Vinyl 303: Printable Polyvinyl Chloride Filament All 3DP

Source Link

ABS Pro Filament – What is it? All 3DP

Source Link

Matterhackers MH Build Series PLA 3D Printer Filament Review All 3DP

Source Link

Nefilatek, a Montreal-based startup that specializes in making recycled filaments, has developed 3D printing filaments made from 100% recycled plastic.

The company operates a Kickstarter page where early adopters can choose between two types of filaments: Nefila HIPS (High Impact Polystyrene) Black and Nefila PC (Polycarbonate), which come with reusable spool bobbins and environmentally friendly packaging. With its new filaments, Nefilatek wants to offer a “safe alternative solution for manufacturers, designers and manufacturers” that reduces the amount of plastic that is used and wasted in 3D printing.

The filaments from Nefilatek. Photo via Nefilatek.

Reducing the environmental impact of 3D printing

Nefilatek was founded in 2018 by two engineering students who both admired the capabilities of 3D printing that allowed inventors, product designers, and manufacturers to get their products to market faster, but were disillusioned with the environmental impact of the technology. They founded the company to combat the huge consumption of plastic in the 3D printing industry, a material that is a major environmental pollutant.

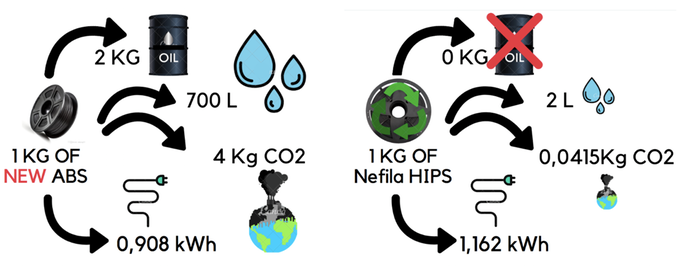

Nefilatek claims that the annual plastic consumption from the 3D printing industry is an estimated 30 million pounds, with a projected 250 million pounds by 2020. Currently, according to the company, it is also estimated that the production of 3D printing plastics will result in consumption of 1.4 Million barrels of oil that will generate over 800 million pounds of carbon emissions annually by 2020.

The Nefila HIPS and Nefila PC filaments

Nefilatek’s recycled filaments aim to have “less impact on the planet” for 3D printing. The company’s first filament, Nefila HIPS Black, is made from high-impact polystyrene recycled from Montreal’s electronic waste. The filament’s benefits include impact and heat-resistant 3D prints, while Nefilatek claims it maintains the same properties as standard ABS. The HIPS filament can also be dissolved and smoothed with the sustainable oils D-limonene and turpentine.

The company is currently conducting final testing of its Nefila PC filament extrusion process prior to commercialization. The filament consists of 100% thermoplastic polycarbonate polymers and is geared towards technical applications due to its firm and flexible mechanical properties. It is also resistant to large temperature fluctuations (-50 ° C to + 130 ° C).

Nefilatek is also working on developing a white variant of its Nefila HIPS filament and is also ready to conduct research and development tests on various other materials, including nylon and polypropylene. Since beginning development of its filaments in 2018, Nefilatek launched a Kickstarter in January 2019 to fund further research and development of its filaments with the aim of bringing them to market. The company plans to ship its Kickstarter filament orders in June 2019.

Standard filaments compared to Nefilatek’s recycled filament. Image via Nefilatek.

Standard filaments compared to Nefilatek’s recycled filament. Image via Nefilatek.

Filaments made from recycled materials

Several other initiatives have also been launched to help reduce the environmental impact of 3D printing by using recycled materials to make 3D printing filaments. Examples of this are the British brand’s ONE PET filament for 3D printer filaments Filamentous. The company offers a 100% recycled plastic filaments Made from PET plastic bottle waste for end users. ONE PET was produced in collaboration with Tridea, a company that specializes in converting plastic waste into 3D filaments.

In addition, researchers from the US Army Research Laboratory (ARL) have also used Recycled (PET) plastic found in water bottles, yogurt containers, and other recyclable waste materials 3D printing filaments. By using reclaimed materials, service members can quickly use 3D printing to create replacement parts for military vehicles, weapons and equipment.

You can now cast your vote for the third year 3D Printing Industry Awards. Help determine this year’s winners nowand choose the best initiative with 3D printing to create a better world.

Subscribe to the 3D printing industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us Twitter and like us Facebook.

Looking for a career in additive manufacturing? visit 3D print jobs for a selection of roles in the industry.

The picture shown shows filaments from Nefilatek. Photo via Nefilatek.

Market leader in desktop 3D printing, MakerBothas announced its first specialty material offering for the METHOD 3D printer.

Users of the recently introduced performance system can now print with polyethylene terephthalate glycol, better known as PETG, to make parts for industrial applications, including functional prototypes, fixtures and fittings, and end-use components.

“PETG is the first product in a new range of materials for METHOD. Our customers have asked for different materials for a wide variety of applications that require high strength and durability, ”said Nadav Goshen, MakerBot CEO. “PETG is one of the most widely used polymers today. Because of its advanced properties and versatility, we consider PETG an excellent material for the production line and short-term production runs. “

This industrial grade material is expected to ship in June and has a heat deflection temperature of up to 70 ° C and strong layer adhesion to reduce shrinkage and warping during printing. PETG is moisture resistant and contains many chemicals and prints with a glossy surface and a good degree of ductility. It can also be used with METHOD’s water soluble PVA with double extrusion for complex parts and effortless removal of the carrier.

METHOD Specialty materials are intended for users looking for advanced material properties. They provide basic printing performance and may require additional workflow steps to print successfully. According to MakerBot, PETG requires a glue stick to be applied to the build plate before printing.

This latest specialty material also compliments MakerBot’s line of precision materials specifically designed for the METHOD printer, including MakerBot Tough, MakerBot PLA, and MakerBot PVA.