(as of Jan 18, 2026 18:00:07 UTC – Details)

Product Description

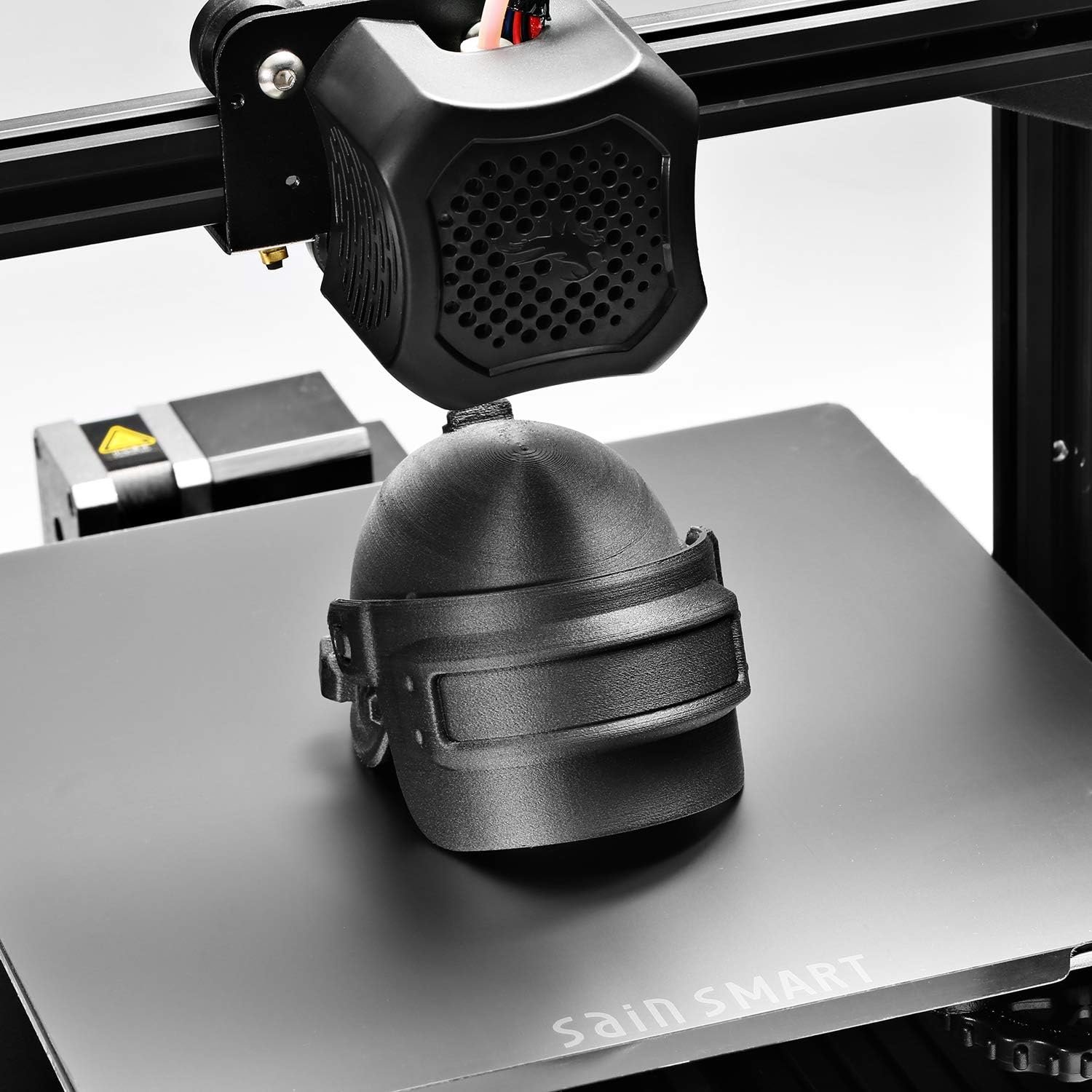

Matte surface effect

Carbon fiber nylon filament is not easy to warp and crack when printing, and the surface of printed models is matte and delicate.

High strength

80% Nylon Coupled with 20% Carbon Fiber, which makes it higher rigidity and strength than normal nylon filament.

Wide Application

PA6-CF is very strong, and durable and features excellent heat resistance for making both strong and flexible industrial parts, prosthetics, bicycle pedals, etc.

Tips

Ensure that your printer is capable of handling carbon fiber nylon filament. It’s best to use a printer with a full metal nozzle, as carbon fiber can wear down standard brass nozzles.Printing Temperature: The printing temperature for carbon fiber nylon typically ranges from 260°C to 280°C.Bed Temperature: The print bed usually needs to be heated to between 60°C and 80°C to enhance adhesion and minimize warping.Printing Speed: Usually between 30mm/s and 60mm/s, and high-speed printers can reach 80mm/s. Nozzle Diameter: Using a larger nozzle diameter (such as 0.4mm or larger) can reduce the risk of clogging and improve printing efficiency.Platform: Use platforms such as PEI, and glass to improve adhesion during printing. Storage: Carbon fiber nylon is sensitive to humidity, so it’s recommended to store it in a dry environment using sealed bags or a drying box.

Filament Properties

Density 1.24 g/cm3 Melt Flow Index 11.46 (275℃/5kg) Tensile Strength 140 MPa Elongation at Break 10.61% Flexural Strength 140 MPa Flexural Modulus 4363 MPa IZOD Impact Strength 18.67 kJ/㎡ Heat distortion Temperature 155 (℃,0.45MPa)

[Incredible Strong] We use a new formula to improve its rigidity and print performance: 80% nylon coupled with 20% carbon fiber, which is ready to take on your next project. With no less than 20% Nylon based carbon fiber SainSmart CF20 is Easy to print, with great surface finish and strength to take on some of your most demanding jobs.

[Lower Shrink Rate] It features with lower shrink rate, higher strength, and rigidity, less warpage and more resistant to wear and tear compared to the traditional nylon filament.

[Smooth Printing] Produce high-quality parts that are easy to process and look great; all while delivering functionality, stiffness, dimensional stability and heat resistance in an easy to print material.

[Application] It is suitable for those looking to make both strong and flexible industrial parts, prosthetic, medical equipment, and complex costumes, etc. Optimal print temperatures of 260 – 290°C(500-554°F) with a build surface temperature of 45-80°C make it a great choice for professional and home 3D printers.

[Tips] Carbon Fiber is abrasive and in general, these fibers will rapidly accelerate the nozzle-wear of brass nozzles. It is highly recommended that you use nozzles made from Stainless steel or other hardened alloys. For better layer adhesion and strength, a constant ambient temperature is needed, we recommended you to print in a enclosure or with an enclosed printer to get the best result.