(as of Dec 23, 2025 14:00:05 UTC – Details)

Product Description

iSANGHU Carbon Fiber Nylon6 Filament

About iSANGHU PA6 Carbon Fiber Filament

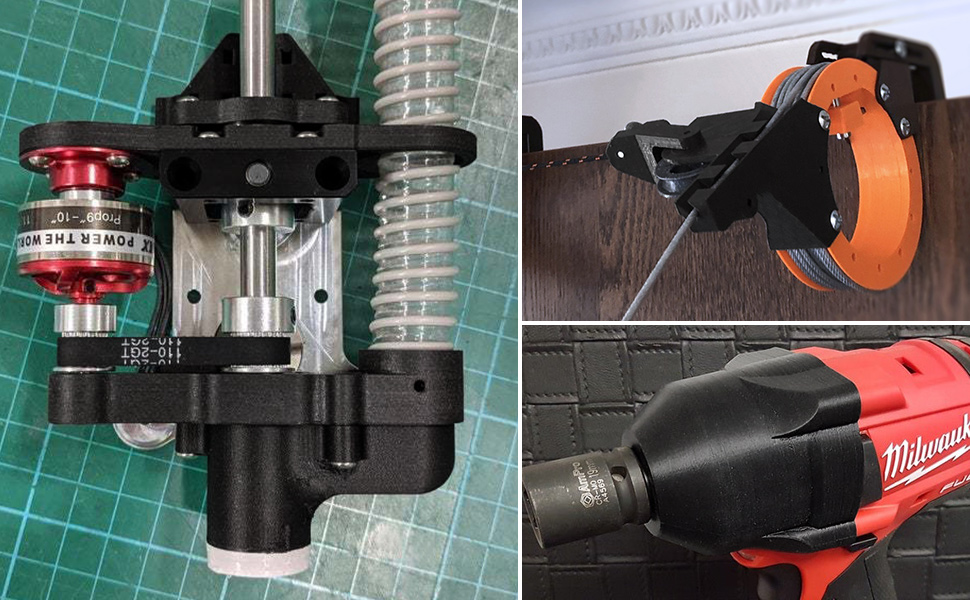

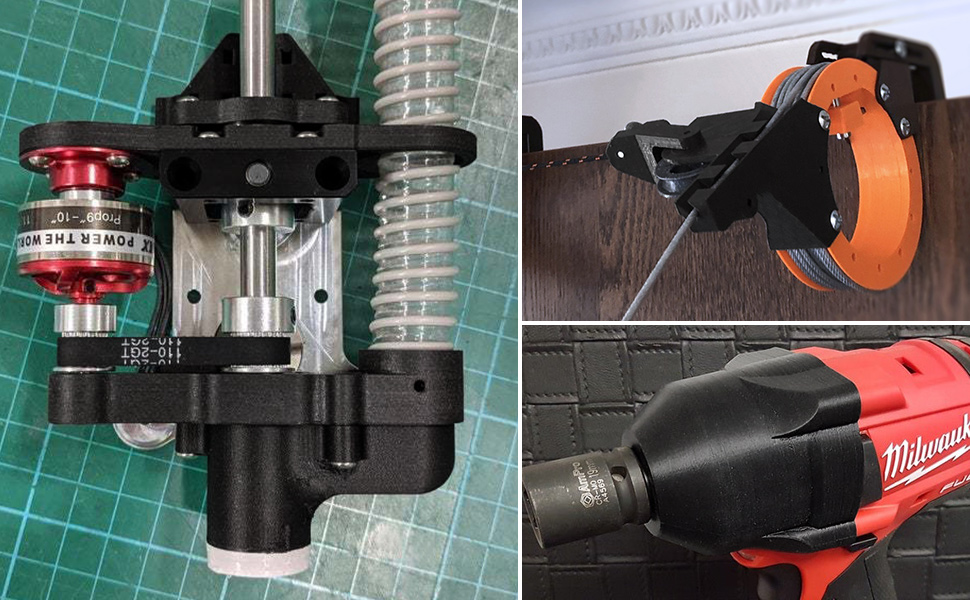

iSANGHU PA6-CF Filament is made using a specialty Nylon 6 copolymer and high-modulus carbon fiber. Its higher modulus, higher mechanical strength, and higher rigidity are further improved, and also bring better printability, dimensional accuracy, and lower shrinkage. It is commonly used in 3D Printing for applications requiring torsional, tensile, and impact strength, such as functional prototypes, tools, fixtures, end-use parts, pump impellers, mechanical gears, and precision and engineering components in robots, drones, automotive and aerospace industry.

Engineered Precision and Material Property:

Material: 85%PA6+15%CFColor: Matte BlackFilaments Net Weight: 1 kg (2.2 lbs)Diameter and Accuracy: 1.75 mm +/- 0.02Packaging: Vacuum sealed with desiccantNozzle: Stainless steel nozzle and larger nozzle (0.6mm or larger)Compatibility: PA6 carbon fiber filament can be used in all printer bases that meet the requirements of a bed temperature of 80-100°C, a nozzle temperature of 250-290°C and an enclosure. Such as Bambu Lab X1, MK3, Creality K1/K1 Max, Raise3D Pro2, Ultimaker S5, Prusa i3 MK3S, Monoprice FlashForge, etc.

Specification and Print Settings

Dimensional Accuracy+/-0.02mm that maximizes precision printing performance and compatibility with all major FDM printer brands. It is an ideal choice for high-performance applications.

Recommended Extrusion/Nozzle Temp: 250 – 290℃ (480℉~ 554 ℉)Bed temperature: 80 – 100°C(176 – 212°F)Printing speed: 30 – 100mm/sSuggested bottom plate type: High temperature smooth PEI board/smooth PEI boardSuggested gluing: solid glue stickFloor height: 0.2mm

Toughness & Vibration Resistance

Polyamide 6 (PA6) carbon fiber filament is known for its toughness and vibration resistance, making it a popular choice in various engineering and manufacturing applications.

High Mechanical Strength

PA6 carbon fiber printer filament has higher strength and rigidity, Better Impact Resistance than regular PA6 filament material. suitable for applications requiring torsional, tensile, and impact strength.

High strength-to-weight ratio

iSANGHU carbon fiber PA6 3d printer filament 1.75mm has a very high strength-to-weight ratio and is extremely rigid.

Heat and Chemical Resistance

iSANGHU PA6 carbon fiber filament 1.75mm is tough and heat and Resistance resistant enough to be used in the harsh environments

Wide Applications

Tips:

1. Please keep it in a sealed bag or box after using and dry it at 80℃ more than 10H before printing.

2. Carbon fiber black PA6 filament 1.75 might wear nozzles and extruder gears, it is recommended to use hardened steel nozzles or ruby nozzles, hardened steel extruder gears will be better.

3. Please insert the filament into the reel hole after use to avoid tangles.

4. If there is no print plan within a couple of days, retract the filament to avoid clogging the nozzle.

5.When 3D printing with support structures, it’s important to remove the supports within 2 hours to avoid difficulty in removal after they become damp and softened. If the supports are hard to remove, dry the prints, let them cool down, and then remove the supports promptly.

6.Due to differences in printer compatibility, if you have any questions about the printing effect, we suggest that you adjust the printing speed to 30-60mm/s, set the bed temperature to 100 ℃, and set the printing temperature to 260-280 ℃.

NOTE:

Because of shooting light or display resolution, there are some color differences between the pictures and objects.

Technical Properties(Based on ISO Standards)

Density (ISO 1183) 1.135 g/cm³ Tensile Strength (ISO 527) 46 Mpa Elongation at break (ISO 527) 5.2 % Tensile Modulus (ISO 527) 5 Gpa Flexural strength (ISO 178) 135 Mpa Flexural Elongation (ISO 178) 4.5 % Flexural Modulus (ISO 178) 5 Gpa Impact strength, 1eU (ISO 179) 74 kJ/m² Impact strength,1eA (ISO 179) 7.95 kJ/m²

Add to Cart

Add to Cart

Add to Cart

Add to Cart

Add to Cart

Add to Cart

Customer Reviews

4.0 out of 5 stars 617

4.0 out of 5 stars 617

4.0 out of 5 stars 617

4.0 out of 5 stars 617

4.0 out of 5 stars 617

4.0 out of 5 stars 617

Price

$38.99$38.99 $69.79$69.79 $42.99$42.99 $24.99$24.99 $21.99$21.99 $20.99$20.99

Filament Type

85%PA6+15%CF 85%PA12+15%CF 80%PC+20%CF 80%ASA+20%CF 80%ABS+20%CF 80%PETG+20%CF

Tensile Strength (X-Y)(Mpa)

47.6 68.4 34.64 44.71 30.84 30.23

Elongation at Break(%)

5.27 12.573 6.74 5.15 6.47 4.35

IZOD Impact Strength(Kj/m2)

7.95 28.392 5.45 4.0 3.49 2.99

Nozzle Temperature

250℃ – 290℃ 260℃ – 290℃ 250 – 270℃ 260 – 280℃ 220℃ – 260℃ 220℃ – 250℃

Bed Temperature

80℃ – 100℃ 90℃ – 110℃ 80℃-100℃ 80℃ – 100℃ 80℃ – 100℃ 60℃ – 75℃

Fan Speed

0% 0% 0% 30-50% 0% 30-70%

Printing Speed

30-100mm/s 40-60mm/s 30-100mm/s 40-60mm/s 40-100mm/s 40-130mm/s

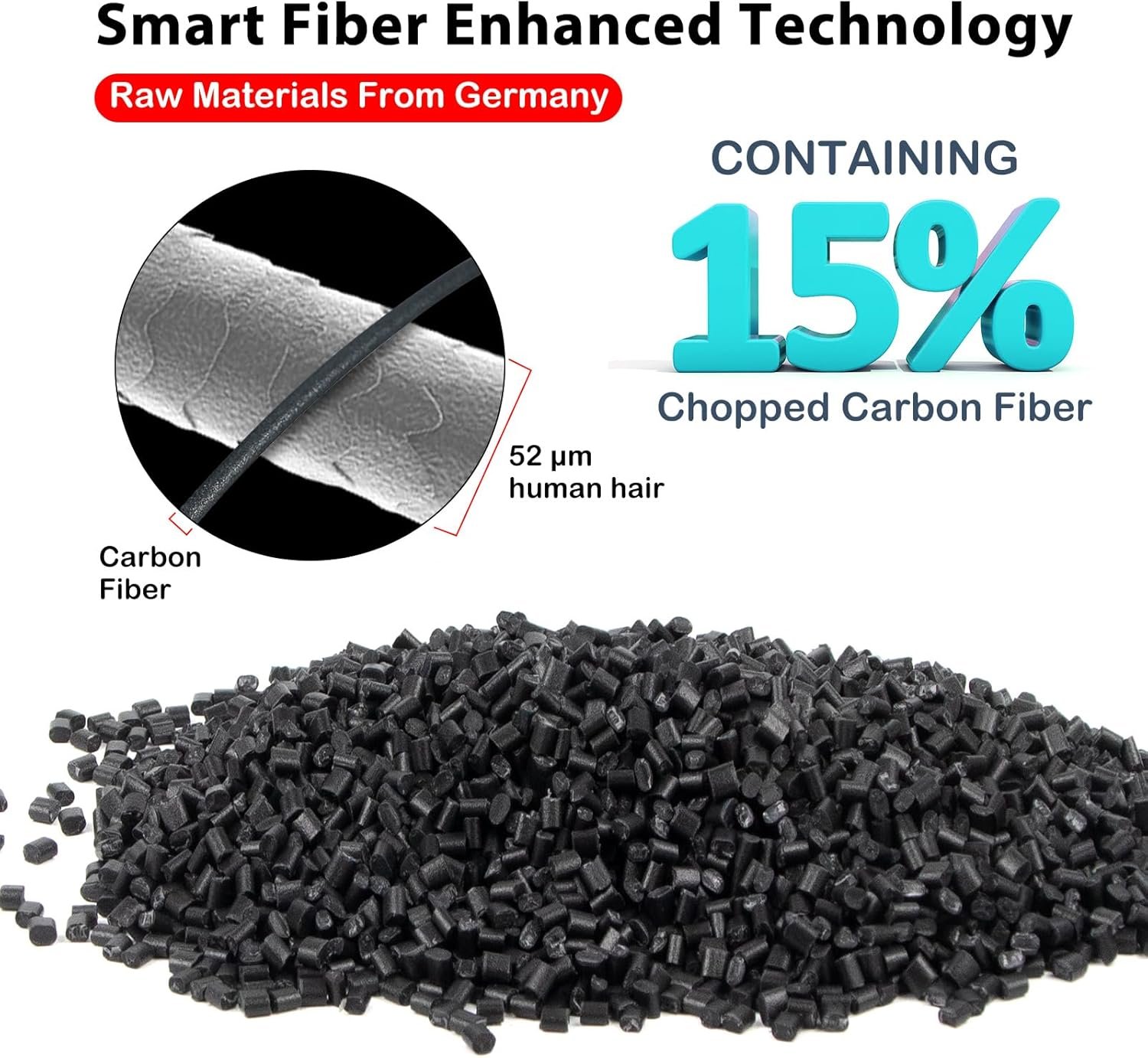

[15% High-Modulus Carbon Fiber Filled Nylon]-The material of iSANGHU Industrial PA6 CF comes from Germany, is a composite filament material that is 15% Chopped carbon fiber filled and based on Nylon 6 (Polyamide 6). This carbon fiber-reinforced material greatly enhances the material’s overall performance and reduces the risk of warping during printing.

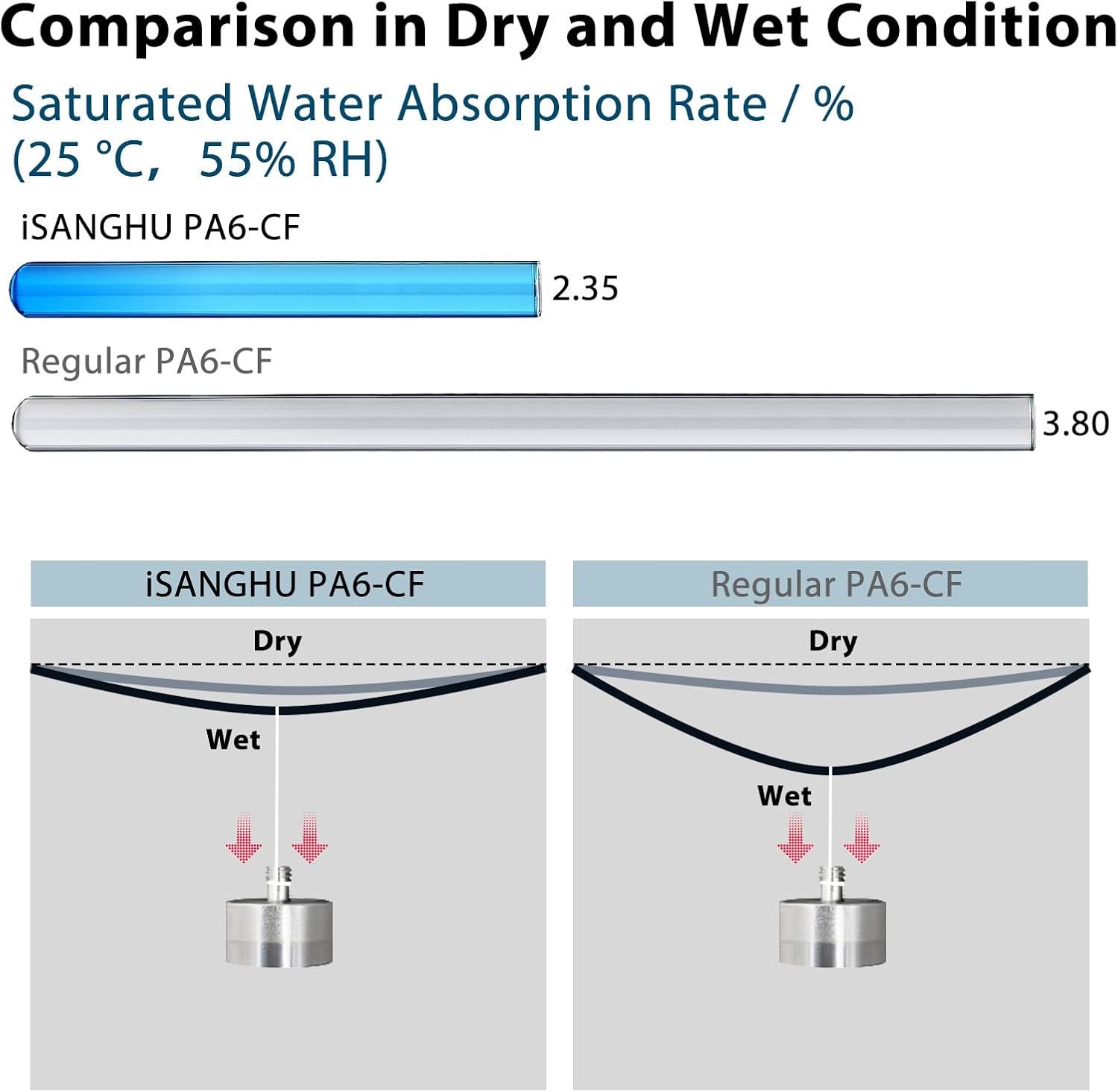

[Excellent Mechanical Properties]-iSANGHU’s PA6-CF has exceptional mechanical properties due to its advanced formulation using high-quality Nylon and chopped carbon fibers. Our Smart Fiber Enhanced Technology ensures optimal dispersion and distribution of carbon fibers during extrusion, resulting in a mesh skeleton structure that bears most of the load transferred by the material matrix to improve mechanical properties, heat resistance, and dimensional stability.

[Stable tolerance & Good Layer Adhesion]-Advanced CCD diameter measuring and self-adaptive control system in manufacturing ensure strict tolerances. Diameter 1.75mm, dimensional accuracy + / – 0.02 mm. The low shrinkage and stable printing dimensions make the fusion between the layers very good to obtain an even better-bridging result.

[Wide Industrial Applications]-The carbon fiber filament 3d printing materials enable lightweight and durability, suitable for applications requiring torsional, tensile, and impact strength such as functional prototypes, tools, fixtures, end-use parts, pump impellers, mechanical gears, precision, and engineering components, widely used in robots, drones, automotive, aerospace and Medical industry.

[Tips for Printing]-The PA6-CF is highly abrasive and can wear out and clog stock 0.4mm brass nozzles rapidly. A larger diameter (0.6mm or more), abrasion-resistant hardened steel or ruby nozzles nozzle is highly recommended, and keep your nozzles clean between every several prints or so. The recommended drying temperature is 80 ℃ for 10 hours in a blast drying oven, or 90 ℃ for 12 hours on a heat bed before printing. Print Temp: 250°C – 290°C, Bed Temp: 80°C – 100°C, Print Speed: 30-100mm/s.