Equipped with a special nozzle, the 3D printer works at a lower temperature and pulls the filament through faster than conventional printers, so that only its outer layer is partially melted to ensure adhesion to neighboring filaments during the 3D printing process. The lower temperature also ensures that the embedded microelectronic components stay cool and solid without being affected by the printing process.

The devices printed with such embedded electronic filaments are either littered with tiny electroluminescent pixels (about 55 µm each) or can spatially resolve light with a resolution of micrometers (when using the light sensor filament) over their entire surface in the centimeter range.

Described in the publication “Structured Multimaterial Filaments for 3D Printing of Optoelectronics” published in Nature Communications, the specially manufactured fibers contain several interconnected materials at the micrometer level, including metal wires, semiconductors with active functions, and polymer insulators to keep wires in contact prevent each other.

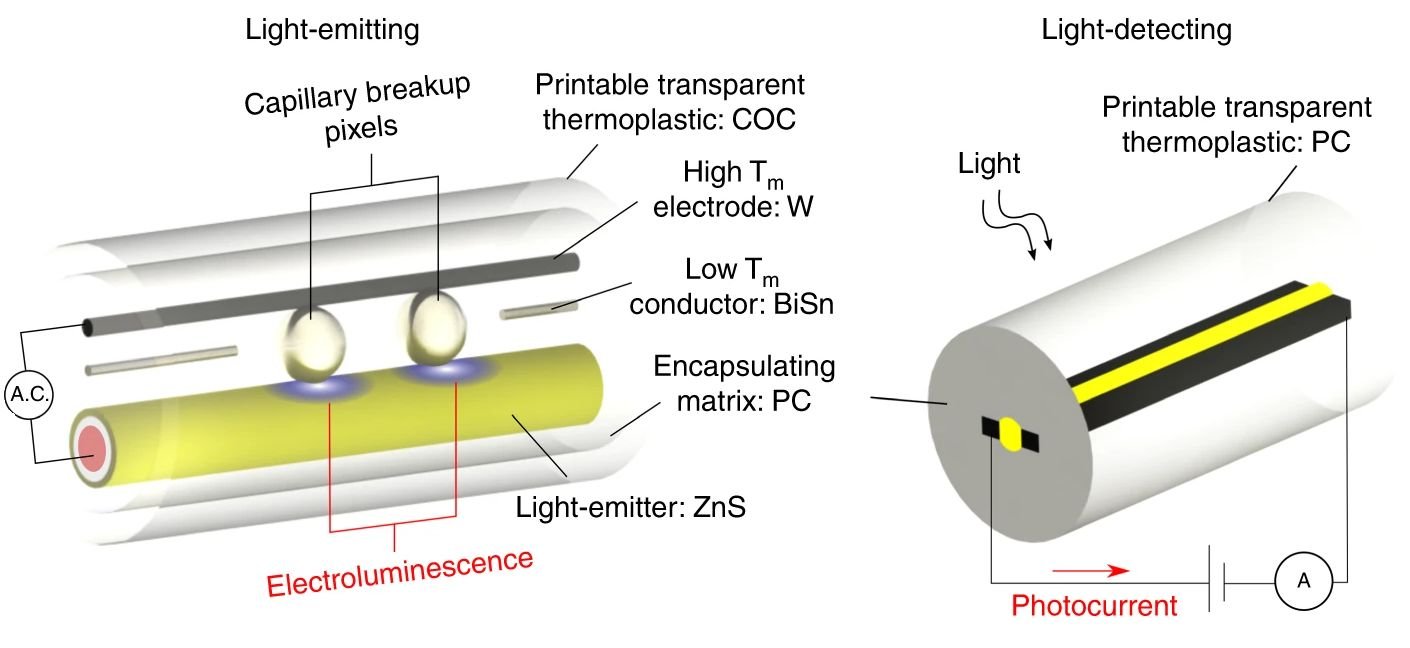

The light-emitting filament consists of a metallic BiSn core (laser-heated in the drawn fiber to form discrete microspheres when the capillary ruptures), electrically conductive tungsten (W) and an electroluminescent ZnS layer, which is wound around a dielectrically coated copper wire. The entire batch is lined with insulating polycarbonate, which is surrounded by a layer of pressure tape (a cyclic olefin copolymer).

Schematic representation of the pixelated light emitting filament (left) and the light detecting filament with an external circuit connected to opposite ends of the different electrodes.

By connecting the tungsten and copper electrodes to an AC voltage source, the bridging microspheres connect the electrical potential from the tungsten electrode to the outer surface of the ZnS, thus enabling sufficient electrical field strength to induce light emission from the ZnS layer via electroluminescence, the paper reports.

Using a regular 3D printing process, the authors found that this 0.6 mm thick filament along its length can give a maximum pixel density of 107 pixels per inch with a pixel resolution of only 55 µm at the level of the pixel size in current high-resolution super- Find Retina Displays.