MakerBot Opens its Methodology 3D Printer to Third-Celebration Filament – All 3DP

MakerBot opens its 3D printer method to all third party filaments 3DP

Source Link

MakerBot opens its 3D printer method to all third party filaments 3DP

Source Link

A new material has been developed that is ideally suited as a water-soluble all-purpose carrier for additive manufacturing (3D printing). Its thermal stability and robust adhesive properties make it an ideal carrier system for a wide variety of building materials.

Most manufacturers know how 3D printing enables them to make stronger and lighter parts and systems. Although many different materials can be used to create 3D printed models, the most common thermoplastics used are acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and polycarbonate (PC).

Complex thermoplastic parts and structures have bridges or overhangs that need to be supported while printing. Since these supports are not part of the model, they must be removed after printing. This post-processing step is important as it affects the final surface finish, strength, and color of the printed part. However, it can be tedious, require the use of harmful chemicals, damage the surface of the model, and decrease productivity. For this reason, it is important to choose the right material for 3D printing support structures.

BREAKAWAY VS. SOLUBLE SUPPORT STRUCTURES

There are two basic categories of materials available for support structures: breakable and soluble. Tear-off support structures are often made from a material that is similar to the printed object. After printing, the carrier is removed by trimming, mechanical breaking or abrasion.

All of these steps add to the labor, and therefore the time and cost of each piece. In addition, removing the 3D printing support structures can leave imperfections on the model surface or break part of the model along with the structure. Also, tear-off props are generally more difficult to remove when working with high temperature materials.

Alternatively, soluble substrates can be removed by adding them to water or a solvent after printing. The use of solvents is undesirable because they are generally volatile organic compounds that are unfriendly to printers and the environment. However, it can also be difficult to work with water-soluble carrier materials. For example, polyvinyl alcohol (PVA) absorbs water vapor from the air, does not adhere very well to printing surfaces, and is temperature sensitive, which can lead to jams. Water-soluble support materials were also extremely difficult to develop.

DEVELOPMENT CHALLENGES FOR SOLUBLE SUPPORTS

The development of water soluble carriers is challenging for many reasons. First, there are a limited number of commercially available resins that are truly water soluble. Many water-soluble polymers are very brittle, which prevents them from converting into filaments. In addition, plasticizing with conventional additives often inhibits thermal stability and adhesion, which severely limits their use in 3D printing.

The first generation of soluble carriers had a number of problems. Some used harmful chemicals or strongly acidic or strongly basic solutions. While some of these are still widely used, resin technology has advanced and there are now a variety of soluble substrates in the commercial market including:

• Highly proprietary resins (Stratasys SR30, SR35, SR100, etc.)

• Resins based on commercially available PVA or polyvinylpyrrolidone (PVP)

• Cellulosic agents such as hydropropylmethyl cellulose (HPMC)

• Exotic polybutenediol vinyl alcohol (BVOH)

However, none of these products are ideal for filaments because they are not thermally stable. Now there is a better material option.

WATER-SOLUBLE RESINS THAT ARE HEAVY ON THE FILAMENT

Infinite Material Solutions recently developed a composite material that is both water soluble and thermally stable. This “out of the box” resin is formulated from a naturally occurring carbohydrate blended with a polymer that is flexible, tough, and water soluble. The new material (branded) AquaSys™ 120) is unique in that it is sturdy enough to be used as a support filament.

This formulation is surprising, since many pure carbohydrates and water-soluble polymers are far too brittle to form a usable filament. Over the years, formulators have made many attempts to plasticize water soluble resins so that they can be converted into filaments. However, the addition of plasticizers often dramatically reduces the thermal stability of the base resin. Plasticizers can also inhibit the adhesion between materials and severely limit their use for 3D printing. AquaSys 120 uses a highly complex process to produce filaments 1.75mm and 2.85mm in diameter that can be successfully used for a wide variety of 3D printing platforms and materials.

MATERIAL ADVANTAGES AND COMPATIBILITY

The individual components of this new material are widely used in industry for a wide variety of applications ranging from packaging and drug delivery to cosmetics and personal care products. The material is hydrophilic, biocompatible, biodegradable, non-toxic and non-carcinogenic based on information available for each individual component.

This new filament material can be used for the most popular 3D printing technologies, including the manufacture of melt filaments and direct material extrusion. It is also compatible with a wide variety of materials including polypropylene, as well as hydrophilic and hydrophobic polymers. It shows excellent thermal stability and other advantages over traditional PVA that make it a more versatile, robust and environmentally friendly material for carrier filaments.

These benefits include:

• Dissolves in water much faster than pure PVA

• Can be printed with a wider range of materials

• Has improved adhesion properties

• Will biodegrade faster than PVA

THERMAL STABILITY AT MUCH HIGHER TEMPERATURES

A leading brand of PVA filament printing at 215-225ºC and a maximum build plate temperature of 60ºC. Alternatively, the AquaSys 120 filament prints at 240-245ºC and a maximum building board temperature of 130ºC.

ADHESION PROPERTIES

The ability to create materials that can adhere to soluble substrates, or vice versa, is critical to successful 3D printing. Poor adhesion between adjacent carrier and building material layers leads to flaking and printing defects.

The new material was developed with improved adhesion properties to address this problem. It is compatible with a wide variety of hydrophobic and hydrophilic materials used in filament-driven 3D printing platforms and continues to be used with new building materials.

Til today AquaSys 120 has been successfully printed with polyamides (nylon), co-polyester (CPE), acrylonitrile butadiene styrene (ABS), thermoplastic polyurethane (TPU), polycarbonate (PC) and polyolefins such as polypropylene (PP). This offers a significant advantage over conventional PVA filaments, which have limited adhesion to CPE, ABS, TPU, PC and PP.

RESOLUTION

In head-to-head dissolution tests with identically printed parts, the new filament material dissolved twice as fast as a leading brand of PVA at room temperature (22 ° C) and more than six times faster at elevated temperatures (80 ° C). 1 shows its kinetics of dissolution against PVA. In contrast to PVA, which can form gels before dissolving and especially at elevated temperatures, the new material dissolves cleanly and without gelation at temperatures> 35 ° C.

DISPOSAL AND BIODEGRADABILITY

The new composite material is based on a naturally occurring carbohydrate that is mineralized very quickly in the environment. The mineralization of this carbohydrate component can take several hours or days. The remaining constituents of the material biodegrade more slowly, but like PVA, they are considered ultimately biodegradable based on respiratory mineralization tests using acclimated sludge from sewage treatment plants.

A new water-soluble carrier material is now available that solves a number of challenging problems in additive manufacturing. This carbohydrate compound takes advantage of the unusual thermal stability and excellent water solubility of a naturally occurring saccharide mixed with a flexible and tough water-soluble polymer. This unique material offers advanced adhesion to a wide variety of building materials, a wide processing window and improved dissolution performance in water without the use of solvents or harsh chemicals.

By: Nathan W. Ockwig, Gavriel DePrenger-Gottfried, Brandon Cernohous, Philip J. Brunner and Jeffrey J. Cernohous

People always tend to push the boundaries of what is possible with a 3D printer. This also applies to [AndrewW1977] when he decided to 3D print a functional full size surfboard.

With just over nine full days of printing, 95 unique pieces and 3.1 kg of PLA (excluding all test prints), this is certainly a monumental project. One of the bigger problems [AndrewW1977] the solution was to avoid air pockets in the board. Ideally, you would just want to have one continuous hollow chamber to easily vent all of the air in the board when heated. [AndrewW1977] decided to overcome this problem by using a zero fill for every single piece. The parts were then connected using alignment pins that have a central hole, thereby connecting all of the hollow chambers.

By using a triangular shape, he managed to print all of the parts without assistance. Once glued together, the entire board was covered with fiberglass and epoxy, similar to traditional surfboard building. Unfortunately due to the current situation with Covid19 [AndrewW1977] stops short of showing us the board in action. If you have a 3D printer at home and have a lot of free time during the lockdown, [AndrewW1977] published all files for his surfboard on Thingiverse.

As [AndrewW1977] indicates that in the video embedded below, other people have already done similar projects. From jet boats to electric hydrofoils, water sports and 3D printing seem to be a perfect match.

New York, September 08, 2020 (GLOBE NEWSWIRE) – Reportlinker.com Announces the Release of Report “3D Printing Filaments Market By Type, End-Use Industry, Region – Global Forecast To 2025” – https: // www. reportlinker.com/p05751086/?utm_source=GNW

1% from 2020 to 2025. The increasing demand for mass customization in the end-use industries has been the main driver behind the growth of the 3D printing filament market to enable complex geometries to be easily manufactured. In addition, the high demand for 3D printing filaments in the medical industry due to the COVID-19 outbreak is expected to fuel the growth of 3D printing filaments in the medical and dental sectors.

The metals segment is expected to grow with the highest CAGR in the 3D printing filament market between 2020 and 2025

The Metals segment is expected to be the fastest growing type in the 3D printing filament market over the forecast period. Various metals such as titanium, stainless steel, and aluminum are widely used to print complex structures for prototyping and making objects for industries such as aerospace and automotive.

Properties such as high material strength as well as resistance to high temperatures and light weight are the factors driving the introduction of metals into the 3D printing filament market. The introduction of metal materials to the 3D printing filament market is in the early stages.

Given the increasing demand for metal materials from the end use industry in developed countries, the metal segment is expected to grow rapidly over the forecast period.

The Aerospace & Defense segment contributed to the highest consumption in the 3D printing filament market

With the increasing demand for plastic and metal based 3D printing filaments for the manufacture of aerospace components and parts, the Aerospace & Defense segment is expected to be the leader in the 3D printing filament market in 2020, investing in 3D printing technology, printers and materials.

The aerospace industry uses additive manufacturing to mass customize its production. 3D printing filaments are widely used in the aerospace and defense industries to make intricate components and parts because they are stronger and lighter than traditional techniques. 3D printing technology enables the more efficient production of complex parts such as nozzle wings, engine parts, space telescopes, metal cannons and rocket parts compared to conventional processes.

Based on the region, Asia Pacific is projected to grow with the highest CAGR in the 3D Printing Filament market between 2020 and 2025

The Asia Pacific 3D Printing Filament market is expected to grow with the highest CAGR between 2020 and 2025. China had the largest share of the global 3D printing filament market in 2019, which is driving the growth of the Asia-Pacific region.

China, Japan and South Korea are the lucrative markets for 3D printing filaments in the Asia-Pacific region during the forecast period. The growth is due to increasing demand for 3D printing filaments from the aerospace, medical and automotive industries in the region, particularly from China and Japan.

Breakdown of the Primary Interviews for the 3D Printing Filament Market report

• By type of company – Tier 1 – 30%, Tier 2 – 50% and Tier 3 – 20%

• By designation – C-Level – 20%, D-Level managers – 30% and others – 50%

• By regions – Europe – 40%, Asia-Pacific – 30%, North America – 20%, Rest of the world – 10%

Leading manufacturers of 3D printing filaments featured in this report include Stratasys Ltd. (USA), 3D Systems Corporation (USA), Koninklijke DSM NV (Netherlands), Materialize NV (Belgium), Evonik Industries AG (Germany) and Arkema SA (France), Saudi Basic Industries Corporation (SABIC) (Saudi Arabia) , DuPont de Nemours, Inc. (USA), BASF 3D Printing Solutions GmbH (Germany), HP Inc. (USA), EOS GmbH – Elektrooptische Systeme (Germany), Shenzhen Esun Industrial Co., Ltd. (China), CRP Technology Srl (Italy), EnvisionTEC GmbH (Germany), Oxford Performance Materials, Inc. (USA) and MG Chemicals (Canada).

Research reporting

The report covers 3D Printing Filaments market by Type (Plastics, Metals, Ceramics, and Others), by End Use Industry (Aerospace & Defense, Medical & Dental, Automotive, Electronics and Others), and by region. The further breakdown of the type segment by material includes plastics (ABS, PLA, TPE, PA, photopolymers and others), metals (titanium, aluminum, stainless steel, nickel and others) and ceramics (glass, quartz glass, quartz and others)).

The study aims to estimate the size and future growth potential of the market in various segments. It also includes an in-depth competitive analysis of the key market players along with their profiles and growth strategies.

Main benefits of purchasing the report

From a findings perspective, this report focuses on different levels of analysis, such as: B. Industry analyzes (industry trends) and company profiles. With these insights, the study discusses the fundamental views of the competitive landscape, emerging and high-growth segments, high-growth regions, drivers, restraints, opportunities, and challenges in the 3D Printing Filament Market.

The report provides insights into the following:

• Market Penetration: Comprehensive information on various products of 3D printing filaments offered by top players in the market

• Product Development / Innovation: In-depth insight into upcoming developments in the 3D printing filament market, R&D activities and new applications in various end-use industries in the market

• Market development: Comprehensive information on lucrative and emerging markets in different regions

• Market Diversification: Comprehensive information on new products, untapped regions, recent developments and investments in the 3D printing filament market

• Competitive Assessment: In-depth assessment of the strategies, products and manufacturing capabilities of leading companies in the 3D printing filament market

Read the full report: https://www.reportlinker.com/p05751086/?utm_source=GNW

Via report linker

ReportLinker is an award-winning market research solution. Reportlinker finds and organizes the latest industry data so you can get all of the market research you need – instantly in one place.

__________________________

Clare: clare@reportlinker.com USA: (339) -368-6001 Intl: +1 339-368-6001

While consumer 3D printers are great for making models or curios, they’re not always up to the task of creating objects that will withstand real-world use. However, this could change thanks to a new pressure thread.

Compact, inexpensive 3D printers typically use a process known as Fused Filament Fabrication (FFF). A plastic thread is heated to its melting point and then extruded through a nozzle. Successive layers of the molten plastic are deposited on top of one another and form a single solid object when they cool and fuse together.

However, according to US Army engineers, items printed in this way tend to be too structurally weak to be used tough and tough by soldiers in the field. This is a shame because if troops could carry small, cheap 3D printers, they could make parts and tools on-site if needed. And while there are printers that use non-FFF techniques to make stronger objects, these machines are large and expensive, making them impractical for field use.

Under the direction of Dr. Eric D. Wetzel, researchers from the Army’s Emerging Composites Team set out to address this problem. Ultimately, they developed a new dual-polymer filament that would allow consumer 3D printers to make much stronger items using their existing FFF hardware.

The material begins in the form of a cylinder with a star-shaped polycarbonate core which is surrounded on all sides by ABS (acrylonitrile butadiene styrene). Using a proprietary device called a thermal draw tower, this cylinder is heated and drawn out into a thin filament.

Once the filament has cooled, it can be wound onto a roll and then used in a standard FFF 3D printer. Items printed from the material are then heated in an oven and then cooled to ensure that the two polymers fuse together thoroughly.

In laboratory tests, such objects were found to be much stronger than those made from conventional filaments – in fact, they exhibited mechanical properties similar to identical objects made using commercial injection molding techniques. The material’s glow time (heat up and cool down) is currently 24 to 48 hours, but the team hopes to reduce that number to four hours or less.

The army is now looking for industrial partners who might be interested in commercializing the technology in order to use it beyond military applications.

An article on the filament was recently published in the journal Advanced Engineering Materials.

Source: US Army Research Laboratory

Ender 3D 3Pro printer New. Solutech 1.75mm PLA Filament Available – Murrieta, CA Patch Patch.com

Source Link

The U.S. Army just unveiled a new type of multipolymer filament for commonly used 3D printers for desktop material extrusion. The new material could be used to make critical parts with higher performance when needed.

Parts made with simple FFF 3D printers have historically had poor strength and toughness, which has prevented affordable printers from being used to supply military parts on-demand, especially on-site. The Army’s new material overcomes these shortcomings and potentially enables soldiers to use inexpensive printers to produce parts that, after a few hours of heat, can achieve mechanical properties robust enough to withstand harsh field operations.

This breakthrough is an important step forward in the Army’s expedition manufacturing, said Dr. Eric D. Wetzel, who leads the Emerging Composites team and serves as research director for soldier materials in the Army Research Laboratory of the US Army Combat Capabilities Development Command. Wetzel’s research encompasses a wide range of technological solutions that can increase the lethality of soldiers by improving the way warfighters fire, move, communicate, protect, and maintain themselves.

“The army wants to be able to print parts on site to simplify logistics by carrying digital parts files instead of physical parts. Until now, however, the technologies for manufacturing high-strength parts in expeditionary environments have not been practical. These printers are too big to start with, power hungry, fragile, or messy, and their raw materials can have special memory requirements. “This technology can enable the army to use inexpensive, simple printers to make high quality parts.

According to the paper, making molten filaments, or FFF, is the most common additive manufacturing technology, but parts made using FFF do not have sufficient mechanical integrity for most engineering applications. The research team used a novel thermal drawing process to create a two-material filament containing acrylonitrile-butadiene-styrene, known as ABS, with a star-shaped polycarbonate core.

This two-material filament is then used as a feedstock in a conventional FFF printer to create 3-D solids with a composite ABS / polycarbonate core mesostructure. This novel DM filament can revolutionize additive manufacturing and allow low-cost printers to produce parts with mechanical properties that compete with injection molded plastics, as stated in the paper.

In ongoing experiments, the army’s research team is experimenting with new material pairings, pressure conditions and annealing protocols in order to further improve mechanical properties and shorten processing times. Your goal is to reduce the current glow times from 24 to 48 hours to four hours or less.

Researchers are using a pilot manufacturing line to manufacture larger quantities of the filament over the next few months and provide material samples for a variety of army’s transition partners.

“The ability to additively manufacture parts from a high-strength polymer using the FFF process at field, division and / or depot level certainly offers warfighters the opportunity to produce better temporary parts much faster – hours compared to days or weeks. and at a significantly lower cost – often pennies compared to ten dollars, said Jeff Wallace, a mechanical engineer with the Army’s C5ISR center at APG. “Soldiers also improvise as needed and often find their own design solutions to the problems they face. Offering a higher strength polymer material to use in the desktop printers they have access to gives them the ability to innovate on the fly to temporarily solve a larger number of delivery and design issues. Your designs would then be sent to the appropriate engineering support activity for evaluation. “

The lab has filed several patent applications for the technology, and one aspect of the technology has already been licensed: thermally drawn filaments using a specialty polymer for use in additive manufacturing. The Army is looking for additional trading partners to accelerate the development and deployment of this technology, which could have broad applicability to a wide range of additively manufactured thermoplastic parts.

New US Army Research has revealed a new multipolymer filament designed for use with low-cost FFF 3D printers. The high tenacity filament is expected to help in the battlefield and produce business critical parts in a timely manner at a fraction of the cost of traditional parts. The study was featured on the cover of the April issue of Advanced technical materials.

Multi-thermoplastic filament

FFF is the most widely used 3D printing technology today due to its low barrier to entry and relatively low cost. However, parts made with FFF tend to have no mechanical strength, so their use is generally discouraged in high-level field operations where they are exposed to harsh combat conditions. U.S. Army research is aimed at overcoming the limitations of readily available filament and instead creating something as sturdy as the warfighters that will use it.

The researchers combined ABS and polycarbonate (PC) to formulate their novel filament. A 3D printer was used to create a solid preform that consisted of a lower temperature ABS shell and a higher temperature star shaped PC core. A thermal draw tower was then used to feed the solid preform through diameter and tension sensors and convert it back to filament. This newly drawn filament was returned as a starting material, but this time as a mixture of ABS and PC, which gave it superior mechanical properties. To complete the process, parts that were 3D printed from the new filament were annealed in an oven for 24 to 48 hours to completely fuse the layers together for additional structural integrity.

The 3D printed parts came out of the heat chamber with ductilities comparable to injection molded ABS parts and fracture toughness values 1500% (15x) higher than those of identical ABS geometries. The researchers concluded that PC infusion helped withstand heat-induced creep and maintain accurate part dimensions during the annealing process. The team hopes to reduce the glow time to four hours or less in the future.

3D printing the preform and drawing the filament. Image via US Army.

Additive manufacturing in the field

Dr. Eric Wetzel, co-author of the study, explains that the army wants to print parts on site to simplify logistics. Moving digital files and raw materials eliminates the need to lug around excessive physical parts. Unfortunately, the technologies for 3D printing high-strength parts in an expeditionary environment have not been practical. The printers are too big, use too much power to operate, are quite delicate in construction, and their raw materials require special storage conditions.

Jeff Wallace, mechanical engineer at the Army’s C5ISR Center at APG, adds, “The ability to additively manufacture parts from a high strength polymer using the FFF process at the field, division, and / or depot level is sure to become an option for warriors give the ability to make better temporary parts much faster – hours versus days or weeks – and at a significantly lower cost – often pennies versus ten dollars. “

Wallace sums it up, “Soldiers also improvise as needed and often find their own design solutions to the problems they face. Offering a higher strength polymer material that can be used in the desktop printers they have access to gives them the opportunity Immediate innovation to temporarily solve a larger number of delivery and design challenges. Your designs would then be sent to the appropriate engineering support activity for evaluation. “

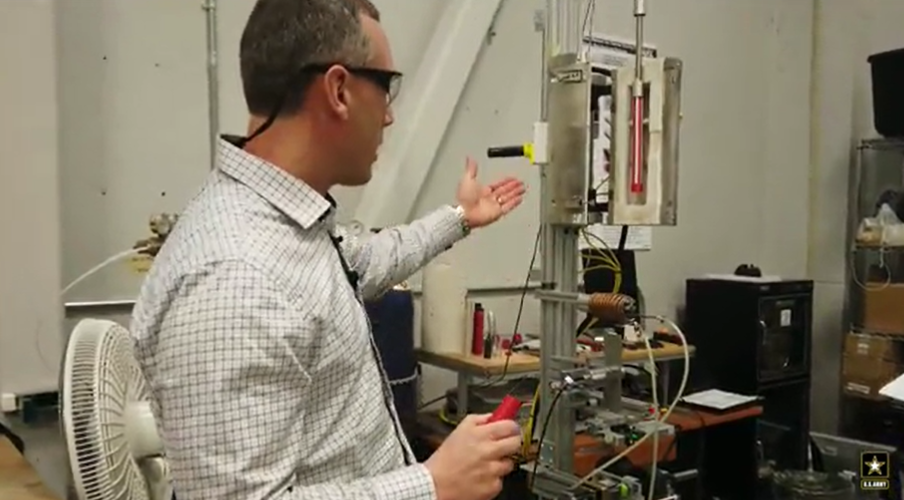

Dr. Eric Wetzel demonstrates the thermal drawing process. Photo via US Army.

Dr. Eric Wetzel demonstrates the thermal drawing process. Photo via US Army.

For more details on the study, see the article entitled ‘Robust, additively manufactured structures, made with double thermoplastic filaments‘. It is co-authored by Kevin Hart, Ryan Dunn and Eric Wetzel.

The U.S. Forces has long used additive manufacturing to manufacture parts and conduct research for their field operations. Earlier this year, tThe US Army announced that it would work towards it Development of its supply chain Support the integration of additive manufacturing. More recently, the army began using the University of Delaware for 3D printing High temperature composites with a Roboze ARGO 500 3D printer.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Now say your word.

Subscribe to the 3D printing industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us Twitter and like us Facebook.

Looking for a career in additive manufacturing? visit 3D print jobs for a selection of roles in the industry.

The picture shown shows the 3D printing of the preform and drawing the filament. Image via US Army.

Choosing the filament is just as important as choosing the right 3D printer. Even with the most expensive printer, you can never get the best results if the filament is selected without proper research and a thoughtful plan. Many things are important when buying the right 3D printer filament. Also, users need to have a thorough understanding of the difference the choice of 3D filaments makes.

We go through so many reviews and feedback when buying a 3D printer, but we often ignore the filament we feed our printer. Not only the quality of the models depends on these materials. Incorrect selection can damage the printer itself. It sounds scary. But don’t worry, if you only have a few points on hand, you will never face such problems.

How do I choose the right 3D printer filament?

Whether PLA or ABS, every filament has its own properties. Not only that, there are many factors that make these filaments different from one another. Choosing the right filament can keep frustration and desperation at bay.

Nozzle diameter of the 3D printer

Photo credit: blog.banggood.com

First of all, you need to be aware that the 3D printers offer different nozzle diameters. Some have interchangeable nozzles, making them compatible with different filament diameters. However, some do not have this privilege.

Hence, you need to check the filament diameter that will fit nicely into the nozzle and will not damage your 3D printer. Most often, 3D printers use a filament diameter of 1.75mm and 3.00mm. Each printer model has its own configuration when it comes to nozzle diameter. And these are designed for certain filament diameters. You can check the 3D printer instructions before placing the order.

There are 3D printers that offer a different filament diameter than the standard printers (1.75 mm and 3.00 mm). So make sure you have the correct information about your 3D printer.

Focus on filament properties

Do you know the filament options are huge? You can choose from PLA, PVA, ABS, nylon and many others. All of these filaments have their own advantages and disadvantages. You can compare these filaments and decide which properties best match the properties of your desired model. You can choose the closest one.

Photo credit: allthat3d.com

PLA: PLA is a biodegradable thermoplastic. It was obtained from renewable raw materials. Hence, the material is known to be the most environmentally friendly, including various other options such as ABS and PVA. Another feature that makes PLA one of the most popular materials is its biocompatibility with the human body. This means you can use it without worrying about allergies or rashes. It’s safe to touch and work with. This is why this material is widely used for medical applications. It has high strength and flexibility compared to the other materials. However, the material can already soften at a temperature of 50 degrees, which is a setback for many users. But a cheap option to start 3D printing.

SECTION: ABS is known for its durability. It’s durable and a bit flexible too. Its heat resistance is relatively higher than that of PLA. To use ABS to print models, users must have a heated bed printer that can be extruded at a temperature of around 225 degrees Celsius. As PLA, ABS is not biodegradable. And it generates fumes when melted at a high temperature. A well-ventilated area must be used when printing with ABS.

PVA: PVA is also one of the most popular 3D printing materials. It’s called polyvinyl alcohol. Printers with twin extruders use this filament to print the support structure. These are soluble in water. Therefore easy to remove after the model has been completely printed. However, PVA requires a special environment for storage and is also expensive.

PETG: PETG is a popular filament. These are very strong and models made with PETG are almost unbreakable. Not only is it a solid material, it is also flexible. In addition, PETG printing is easy and the material is not prone to warping. It provides strong adhesion between layers.

There are many other materials. You need to check out their properties before choosing one. Or, you may not get the results you are looking for.

Choice of filament color

What difference does color bring to the selection process? Not much, but enough to disrupt your printing costs and routine. The natural colors are cheaper than the colors. Due to the inclusion of the pigmentation costs, colored filaments are available at an additional cost. You can also choose transparent colors if you’re looking for a cheap option.

In addition, with colored filaments, the calibration of 3D printers is easier compared to the transparent material.

Supplier selection

As you know, the filaments can be easily destroyed if not packaged properly. Therefore, proper packaging is very important during shipping. Companies that don’t care must be ignored when buying filament for your 3D printers.

If your budget is tight, you can also opt for filament spools instead of buying filament spools. Although spools of filament are easier to handle, they are expensive because of the extra weight they add to the packaging.

The conclusion

There are many filaments you can print with. However, not every filament would help you get the results you want. Additionally, the choice of filaments can make a huge difference to budget. You need to consider all the factors before paying for these filaments. Given the desired properties of your models and the different printing conditions, you can get to the 3D printing material you were thinking about.

Hopefully the above article will help you find the right 3D printing filament and your next printing project would be less frustrating. Knowing which filament highlights the required properties of your 3D printed objects means you can print successfully. They can be good ways to make an amazing difference in print quality.

This article does not necessarily reflect the opinion of the editors or management of EconoTimes.